Coordinate Measuring Machines - CMM ABERLINK - British Made CMMs including the UK's Best Selling CMM the Axiom, the shop floor Extol CMM (2024 Winner of the Kings Award for Innovation), the Horizon linear drive CMM and the NEW Halo CMM. Aberlink Coordinate Measuring Machines are innovative, fast, reliable and accurate with outstanding software and great value whether you are looking to buy or rent. Every Aberlink CMM is designed, manufactured, assembled and software written in the same site in Gloucestershire giving the best possible control over quality, product development and costs. In addition to touch and scanning probe options all Aberlink bridge CMMs have the option of a camera for a truly universal touch & vision measuring machine. Aberlink's 3D measurement software and CAD options set the standard for easy of use and functionality, uniquely Aberlink software upgrades are free for the life of the CMM. The Aberlink range in ascending size is as follows: Fulcrum (manual only), Extol, Axiom, Halo and Horizon, (same sizes, different drive system) and Azimuth. Download the Aberlink Catalogue, get customer opinion from the Aberlink Case Studies and Contact Us for a demonstration or to discuss your requirements. High speed, 24 hour production CMM , 5 temp sensors, auto tool offset correction, robot interface available, simple to use, small footprint, no air supply needed. 2024 Winner of King's Award for Enterprise in Innovation. UK's best selling Coordinate Measuring Machine . Available as manual or CNC competitively priced range of versatile CMMs, replaces Axiom too & the HS variant.

Request Axiom price list (UK). High accuracy, fast, smooth, silent CMM with frictionless linear motors, so there is no mechanical drive system. Ideal for contact scanning. The same structural design as Aberlink's most accurate CMM, the Horizon but with Aberlink's well proven belt drive, great performance and great price. Aberlink's largest CMM and capable of heavy loads A measuring volume of X Axis 1200 mm, Z Axis 1000 mm and a range on Y Axis lenghts from 1000 mm to 3000 mm. With outstanding performance, accuracy and value-for-money, it is the perfect solution for measuring parts up to 6000kg. . The whole philosophy for Aberlink is to make measurement easy.Aberlink 3D software is not only ahead of its competition in being the industry standard for 'easy-to-use' software, but also has the depth of functionality to make it the choice for either occasional users or full-time inspection professionals. Additional modules include CAD Programming and CAD Comparison. Aberlink 3D manual metrology software can be retrofitted not just to other CMMs but also to a huge range of portable measuring arms, including Faro Arms, Romer, Cimcore, Tomelleri and others.

Powerful software for arms, simple and fast to use, great functionality. CAD output as standard and CAD comparison option. Enquire Advanced USB 2 Camera/Vision System Aberlink's CCD camera system offers non-contact measurement on a CMM . A telecentric lens gives distortion-free images on the monitor. Automatic edge detection allows the camera to be used in manual or CNC mode.

Vision Software  ABERLINK Fulcrum (3D measuring using 5 way star)

Accurate inspection right next to your machine toolInspect your parts through every step of the manufacturing process, find failures early. Click and scroll down to see the Fulcrum in action: See the videosThe Fulcrum is a revolutionary manual CMM, by employing three rotary axis Aberlink have created a compact and portable design enabling it to be used where it is needed, on the shop floor near your machine tools, with single touch points, or continuous scanning (ideal for comparison to a CAD model). Rugged, now supplied with a 3 year warranty. Designed to optimize inspection as parts come off the machine one op at a time, feeding back to the machining process at the earliest opportunity, before final inspection, before more expense. A simpler user interface has been developed for Aberlink measurement software, making it even easier to use on a manual CMM, while retaining full functionality. After manually scanning the part, critical features are automatically recognized, and dimensions automatically displayed. Intuitive software and innovative design means you’ll be measuring your parts within minutes of switching on the Fulcrum CMM, even with no prior operating experience. It will quickly become the tool of choice for jump-on, ad-hoc inspection, whether checking 1st off inspection, small batch quality control, or setting CNC machines. The Fulcrum is the easiest CMM to learn and use. Six months CAD Comparison Software free of charge.

One handed inspection. Magnetic soft buttons allow you to quickly change between features without using the mouse. They can be placed anywhere on the measuring surface. You can also program these soft buttons to perform any function in the Aberlink Mk4 software.

Effortless fixturing. Magnetic fixture templates allow you to quickly fixture your part, making sure that all points are taken accurately.

The Fulcrum is supplied with an all-in-one pc and our powerful Aberlink Mk4 software. No air supply required. Ready to measure out of the box, the Fulcrum can identify problems at the root of your production line, saving time and money.

Accurate to less than 5 microns over the entire measurement volume X 280 x Y 280 x Z 150 mm.

See the videos

Contact us for more information or email mike@purduemetrology.co.uk Xtreme - Fast CNC Shop Floor 24/7 unmanned CMM The Xtreme has now been replaced by the NEW rugged and fast EXTOL Shop floor CMM (below) with a larger measurement volume and smaller footprint, more rugged design and five temperature sensors. Make an enquiry

Aberlink Extol - Fast CNC - Production 24/7 unmanned CMM.

2024 Winner of the King's Award for Enterprise in Innovation. 24 hour unmanned CMM, tool offset correction and robot load options please ENQUIRE True to Aberlink’s heritage for innovation, the Extol is the world’s first CMM to utilise a delta mechanism. Designed for robustness and reliability, the Extol CMM will run around the clock making it ideal whether it is positioned next to a machine tool, in a manufacturing cell, or used in a dedicated inspection area. VIDEO

Article in Metrology News Make Enquiry Five temperature sensors monitoring both the machine and ambient temperature ensure that the Extol is capable operating in uncontrolled environments and reporting measurements as though they had been taken at 20 o C. The Automatic Tool Offset Correction available with the Aberlink 3D software compliments the attributes of the Extol perfectly allowing utilisation as part of a fully automated production process in the midst of a manufacturing environment, Can control multiple machine tools and multiple tools. The ergonomics of the Extol have also been a significant design factor. It is not only quick and easy to perform one-off inspections, but also has ample access for either batch inspection or to facilitate automatic loading. With a larger measuring volume and smaller overall footprint than its predecessor, the Xtreme, The Extol can be positioned exactly where the measurement is needed. Robust, accurate and reliable, the Extol CMM is the perfect solution to automatically verify part quality for critical components. Small, slim footprint for both machines tapering at the back in a triangular fashion, can be placed in a corner of a room and the monitors can be fitted either side. Great access for robot loading at either side (when not positioned in a corner).

Choice of two sizes of CMM with measurement volumes of either:

Cylindrical Diameter 370 mm to a height of 270 mm, rising to a height of 365 mm at the centre.

Cylindrical Diameter 520 mm to a height of 300 mm, rising to a height of 400 mm at the centre. Key Features• Fully sealed recirculating bearings proven in the machine tool market significantly improve smoothness and dirt immunity. • A directly coupled belt-drive system eliminates the need for a gearbox and any associated backlash issues. • Swiss-made DC motors and a new Deva motion control system provide exactly the reliability that is needed for shop floor CMM inspection. • The super-smooth belt-drives and linear bearings also enable long styli to be used without suffering false triggering due to vibration. • Automatic Tool Offset Correction and Automation options allow integration into fully automated manufacturing cells. • Automatic temperature compensation allows the Extol to operate in uncontrolled environments and ensures that measurement results are reported as if they had been measured at 20°C • The Extol can support the TP200B probe which uses strain gauge technology, so it does not exhibit lobing characteristics making it ideal for high accuracy applications. In addition, the TP200 probe has a longer life expectancy compared to the TP20, also making it ideal for automated and high-volume applications.

No compressed air required - the Extol is 'plug and go

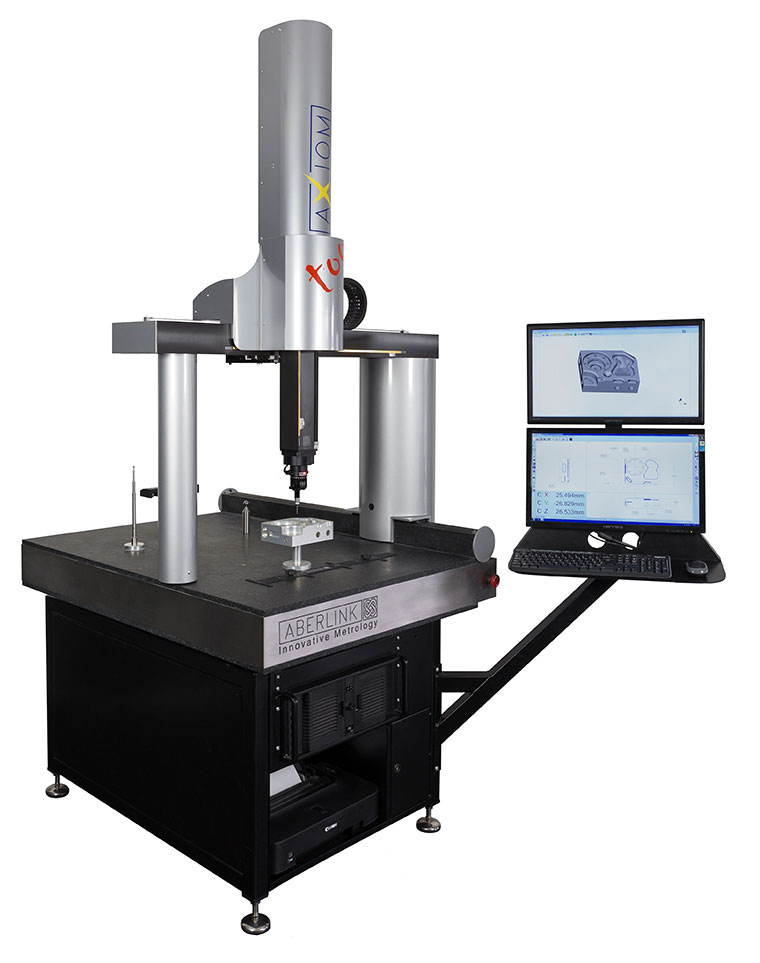

OptionsDual monitors, ideal for use with CAD software options TP20 (standard) offers robust measurement solution TP200B (option) available where high volume or higher accuracy is required 3 or 6 Port change rack, for both TP20 and TP200 (6 recommended for Extol 520 only) Fixturing kit provides a flexible solution for locating components to be measured VIDEO Article in Metrology News Make an enquiry  The UK's best selling CMM - the Axiom too range of manual and CNC CMMs from Aberlink - Innovative MetrologyFast, accurate, reliable and simple to use whether it is it's your first CMM or your tenth the Axiom too CNC CMM is a great choice and it comes in four sizes with Y axis travel up to 1500mm. The best selling Axiom too CMM can be used with touch trigger probe, continuous contact scanning probe or Aberlink’s revolutionary non-contact camera system . giving you a non contact Vision machine . If you would like more information or a demonstration please contact us If you are buying your first co-ordinate measuring machine and would be happier with a manual CMM it's great to know that the Axiom too can be upgraded to CNC when required.

The all aluminium bridge structure not only ensures that the Axiom too CMM has low inertia and high acceleration to get the job done quickly, but also that the temperature of the machine rapidly follows the temperature of the room, ideal when the CMM is not housed in a controlled environment ideal for shop floor inspection and measurement. Temperature compensation in the software reports results as if they had been measured at 20°C/68°F The standard high-tech granite and aluminium table, originally developed for the optics industry, provides fantastic natural damping of high frequency vibration and loading up to 300kg, alternatively solid granite is available at the same price and can take components up to 500kg. The granite Y beam allows preloading of the bridge air bearings in both directions for superior accuracy. Free software upgrades for the life of the machine Make An Enquiry

Aberlink are the largest UK owned manufacturer of CMMs and all the CMMs are designed, manufactured, assembled and software written in the UK on one site in Eastcombe, Gloucestershire, ensuring excellent control over quality, product development and manufacturing costs. Uniquely, Aberlink do not charge for CMM software upgrades giving a significant reduction in the cost of ownership. For a successful company an Axiom too CMM is a necessity not a luxury Why have expensive CNC machines waiting to be set?

Why tie up skilled personnel carrying out slow traditional inspection?

Why loose customers because you supplied out of tolerance parts?

Attract more profitable work with a leading edge inspection centre.

Some features can only be accurately inspected with a CMM.

Intuitive software for the first time user means you are seeing the benefits fast. Inspection wastes thousands Are you still using traditional methods of inspection, while expensive CNC machines are idle, or worse, your inspections are inaccurate or missed out altogether?

Now at last with an Axiom too CMM you can dramatically reduce inspection times and improve setting times throughout your business.

Example No of CNC machines - 5

Time saved in inspection and setting (per machine, per shift) - 0.5 hrs

No of shifts per day - 1

Daily time saved for inspection and setting - 2.5 hrs

Hourly rate - £50

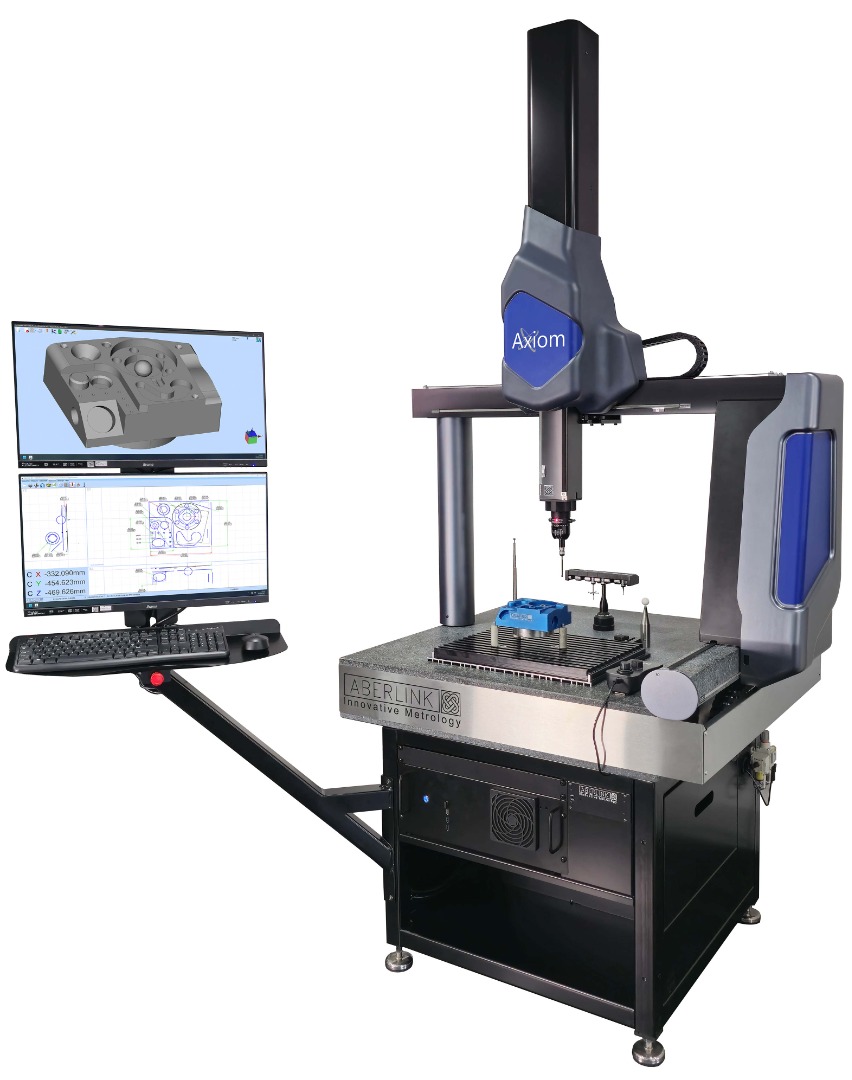

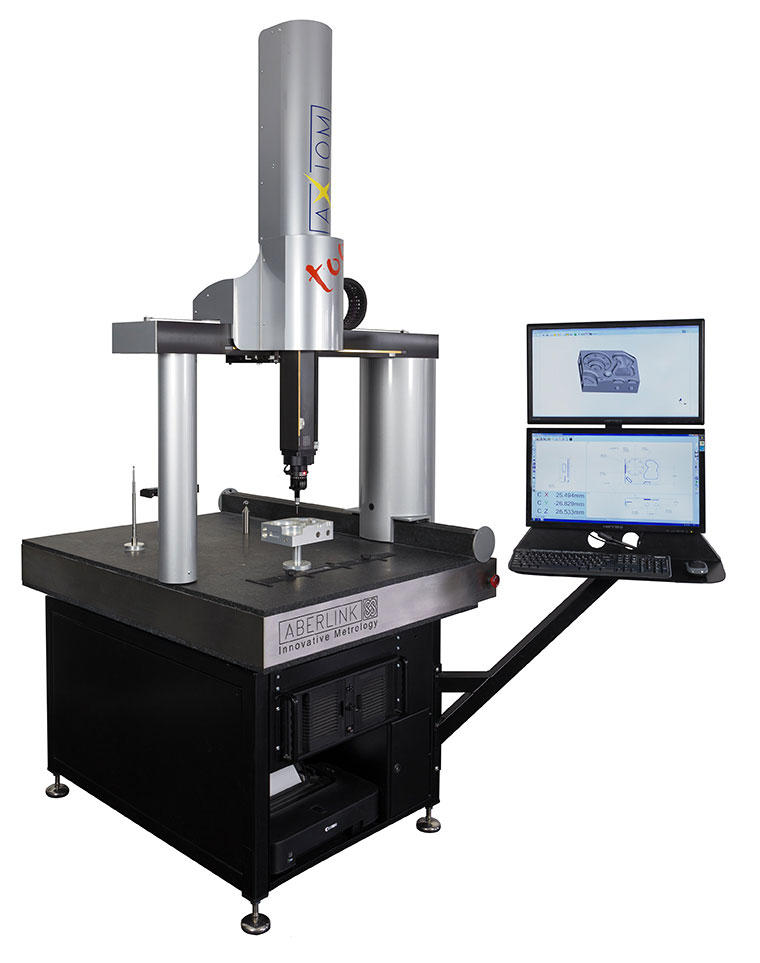

Total annual inspection saving - £31,250  . NEW Axiom - High Spec CMMThe best selling Aberlink CMM just got even better!The Axiom too has been the UK's best-selling range of CMM with thousands of machines sold around the world since 2004.

The brand-new Axiom is the latest evolution of this well respected CMM. It will replace both the standard Axiom too and it's High Spec variant the Axiom too HS having the price of the former and the speed and accuracy of the latter.

Employing a stiffer bridge design, incorporating a wider air bearing separation, means the latest Axiom has further improved on what was already a great package. Being faster, more accurate, and just as reliable, this improved Axiom is set to continue being the CMM of choice in it’s target market. With three different measuring volumes available utilising Y-axis travels up to 1200 millimetres, there is an Axiom to suit every small to mid size application.

Available as either a manual machine or with full CNC control. Key Features- Aberlink's easy-to-use measurement software (now standard on many OEM systems)

- Shortest learning curve of any similar system - 1 day without prior CMM experience

- Smallest overall footprint of any equivalent size CMM

- Choice of Y-axis sizes ranging from 600mm to 1500mm

- Suitable for the workshop environment

- Fitted with 0.0001mm linear encoders for superior accuracy

- Anti-vibration protection from local machine tools as standard

- Ergonomic touch sensitive 3D joystick and variable speed control

- Comprehensive range of probing options and accessories

- Temperature compensation option for workshop environments

- Optional CMM camera system option for non-contact inspection and measurement

- Free stylus change rack with every motorised probe head upgrade*ISO 10360-2:2009 and VDI(U3) accuracy specification.

†Solid granite CMM table loading 500Kg, granite and aluminium honeycomb CMM table loading 300Kg.

Prices exclude vat

Options- CAD Comparison software module for measuring complex components against IGES or STEP models

- CAD programming software , online or offline

- Huge choice of Renishaw, probe holders, probes and modules

- Toolchange Rack - Allows the probe stylus to be changed automatically

- USB II CCD CAMERA system For non-contact measurement – with built-in light ring & manual focus lens

- CMM Collimated light - Enables backlight illumination of 3D or turned components.

- Fixture Logic Kit - with a range of base plate sizes

- SMC IDFA Series Refridgeration Air Dryer

Aberlink are the largest UK owned manufacturer of CMMs and all the CMMs are designed, manufactured, assembled and software written in the UK on one site in Eastcombe, Gloucestershire, ensuring excellent control over quality, product development and manufacturing costs. Uniquely, Aberlink do not charge for CMM software upgrades giving a significant reduction in the cost of ownership.

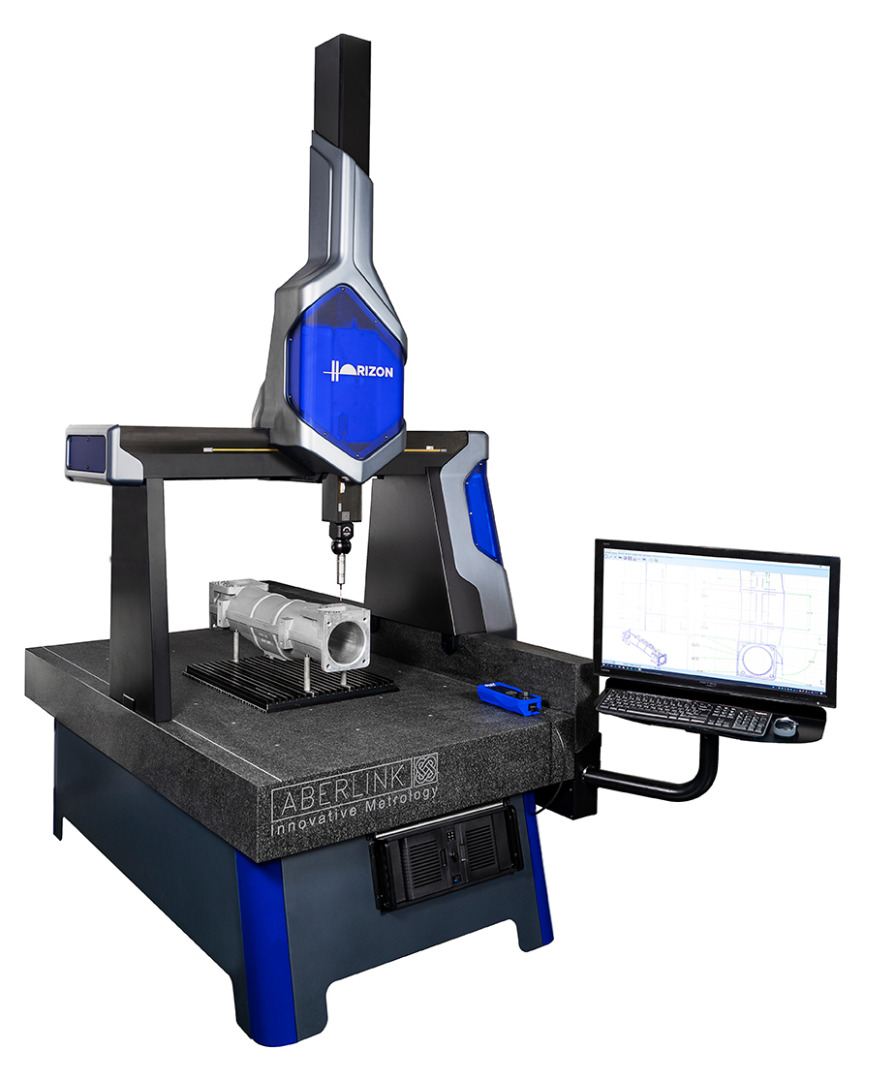

Useful short CMM demonstration video Axiom too HS Make An Enquiry  Horizon CMM - Aberlink's most accurate CMM using new CMM 'linear' drive technology Starting the linear drive revolution, ideal for a scanning CMM Frictionless linear drives are the key to the Horizon’s fast and exceptionally smooth motion, ideal for a scanning CMM, form measurement and complex shapes. The innovative kinematic isolated drive structure is completely independent of the CMM structure. By driving the bridge through its centre of gravity the Horizon’s design gains all the metrology benefits of a CMM with a raised Y axis guideway, but without having the inconvenience of associated limited access.

Video

Make Inquiry

Being non-contact, the linear motors will also have no wearing parts and provide the perfect solution for CMM drives, improving reliability and reducing maintenance. The result of all this novel design is that we have now produced a stand-out machine with fast, smooth, silent motion ideally suited to contact scanning and with a first-term accuracy specification of under two microns.

The Horizon is now available with two bridges sizes:

X axis 800 and Z axis 600

X axis 1000 and Z axis 800 (Horizon L Large)

Both with a range of Y axis bed lengths.

Horizon Data Sheet

Read the Metrology News Write Up

Video

Make Inquiry  Aberlink's NEW Halo & Halo L Medium / Large Shop Floor CMMs(The popular Zenith 3 has now been replaced by the Halo L large CMM) The Halo CNC CMM has the same structural design as Aberlink's most accurate CMM, the Horizon.By using a belt drive system for the X-Y-Z axis movement, the Halo CMM is the perfect mid-sized CMM for use in an inspection department or on the shop floor. The price is also extremely competitive when compared to other international CMM brands.

Complete turnkey system from £35,500.00 ex. VATHigh performance, high accuracy

The Halo CNC CMM is a standout machine with fast, smooth motion, ideally suited to contact scanning that has a first-term accuracy of better than 1.8 microns!

Unrivalled Reliability

The belt-drive system on the Halo CMM has been designed to provide perfectly smooth machine motion. It provides unrivalled reliability and durability. Bullet PointsLinear motors offer frictionless, smooth, silent motion

Thermal isolation of motors from metrology structure

Smooth motion ideal for contact scanning

Aberlink's revolutionary easy-to-use measurement software

Software upgrades FREE for the life of the CMM

Shortest learning curve of any equivalent system - 1 day without prior CMM experience

Choice of Y axis sizes ranging from 1000mm to 1600mm

Suitable for the workshop environment

Industrial joystick supplied as standard

Free stylus change rack with every motorised probe head upgrade Aberlink Azimuth Large Capacity CMMThe Azimuth is the CMM for measuring large parts, it has the largest measuring volume in the Aberlink range having a measuring volume of X Axis 1200 mm, Z Axis 1000 mm and a range on Y Axis lenghts from 1000 mm to 3000 mm. With outstanding performance, accuracy and value-for-money, it is the perfect solution for measuring parts up to 1500kg as standard with options up to 6000kg. Designed to withstand the shop floor environment, and using Aberlink's easy-to-use software, makes it ideal for measuring large components at the point of manufacture. VIDEO Make Enquiry Key Features- Aberlink's easy-to-use measurement software (now standard on many OEM systems)

- Shortest learning curve of any similar system - 1.5 days without prior CMM experience

- Capable of measuring parts up to 1500kg as standard with options up to 6000kg

- Fitted with 0.0001mm linear encoders for superior accuracy

- Unique self-contained drive system ensures excellent performance over the entire measuring volume

- Choice of Y-axis sizes ranging from 1000mm to 3000mm

- Suitable for the workshop environment

- Anti-vibration protection from local machine tools as standard

- Touch screen CMM joystick

- Comprehensive range of probing options and accessories

- Temperature compensation option for workshop environments

- Optional CMM camera system option for non-contact inspection

- Free stylus change rack with every motorised probe head upgrade

The Azimuth is supplied as a complete turnkey package, with everything you need to start measuring parts from day-one. The Azimuth can be upgraded to suit your needs, see the Probe and Software tabs. Standard Package- Aberlink 3D measurement software for touch probe feature inspection

- Windows based controller, PCI machine controller card and peripherals

- Touch screen CMM joystick

- Azimuth air bearing, aluminium and granite CMM

- 0.0001mm linear encoders fitted to X-Y-Z axes

- Unique self-contained belt-drive system

- Steel CMM control cabinet with lockable door

- Renishaw TP8 manual indexing probe head and integrated probe

- Aberlink probe stylus kit

- Aberlink Ø19mm sphere CMM requalification kit

- Post installation on-site verification test

- User training course - up to 4 trainees

- Aberlink 3D measurement software user guide

- 1/2 day follow up training course within first 12 months

- 12 months full parts and labour warranty

- Free-of-charge telephone helpdesk support

Useful short VIDEO demonstration Azimuth Make An Enquiry

Technical Information | Axis Travel (mm) | X 1200

Y 1000, 1500, 2000, 2500, 3000

Z 1000 | | Overall Size (mm) | X 1940

Y 2000, 2500, 3000, 3500, 4000

Z 3595 | | *Volumetric Accuracy | TP20 (2.9 + 0.4L/100) µm

TP200 (2.8 + 0.4L/100) µm

SP25M (2.6 + 0.4L/100) µm | | Scale Resolution | 0.1µm | | **Optimum Temp Range | 18 - 22°C | | Operational Temp Range | 0 - 45°C | | Table | Solid granite | | Table Load Capacity | 1500kg as standard

Options up to 6000kg | | Max. Velocity Vector | 650mm/sec | | Max. Acceleration Vector | 850mm/sec² | | Air Consumption | 50 l/min (1.8 cfm) | | Required Air Pressure | 4 bar (60 psi) |

*Maximum Permissible Error MPE E according to 10360-2, 2009 within the thermal limits defined for optimum temperature range.

**Installation environmental thermal limits: Rate of change <1°C/hr and <2°C/24hr. Temperature gradient <1°C/m Aberlink are the largest UK owned manufacturer of CMMs and all the CMMs are designed, manufactured, assembled and software written in the UK on one site in Eastcombe, Gloucestershire, ensuring excellent control over quality, product development and manufacturing costs. Uniquely, Aberlink do not charge for CMM software upgrades giving a significant reduction in the cost of ownership.

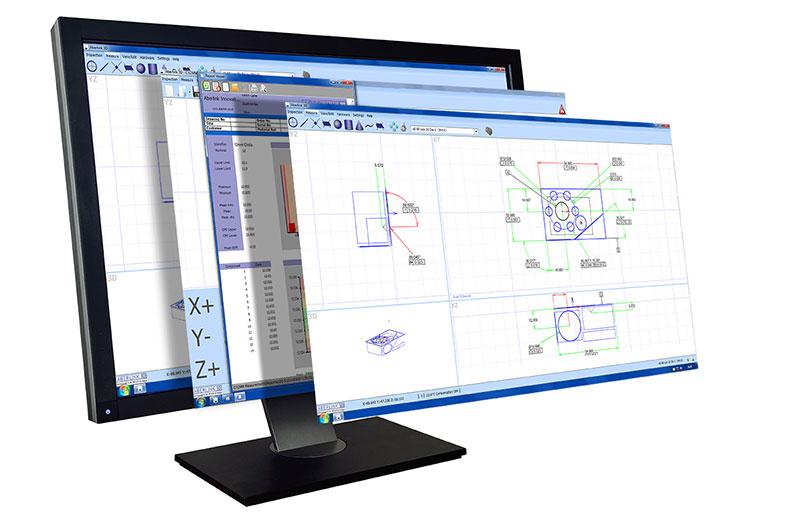

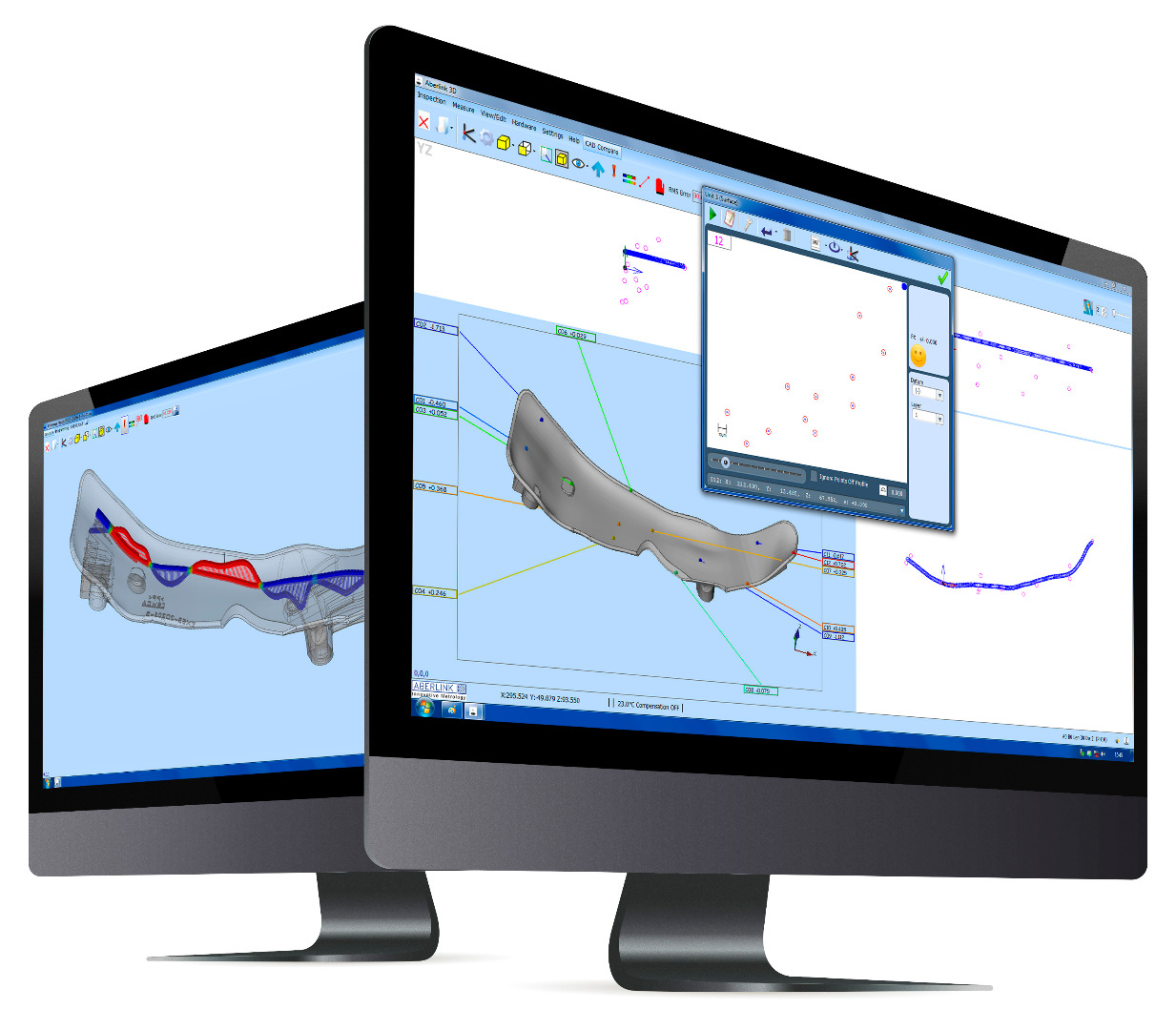

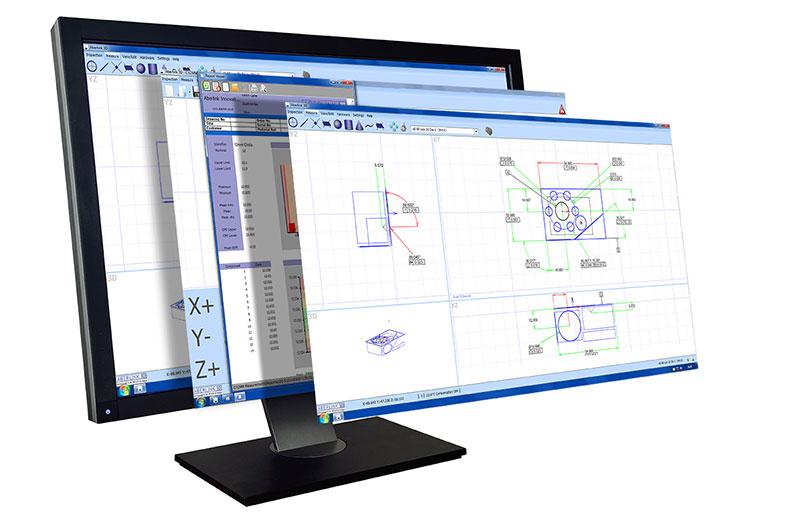

Make Enquiry Aberlink's Revolutionary 3D Measurement SoftwareWhy not view the Aberlink 3D Short Online Demonstration The whole philosophy for Aberlink is to make measurement easy. Aberlink 3D software has been written by engineers for engineers and sets the industry standard for simple-to-use software. Designed around a graphical interface, Aberlink 3D can work in 2D or 3D, on manual or CNC CMMs and is equally at home when used with either touch, scanning or vision systems. It is easy to understand why Aberlink 3D has become the software of choice for numerous manufacturers of measuring devices around the world. Aberlink 3D software is not only ahead of its competition in being the industry standard for 'easy-to-use' software, but also has the depth of functionality to make it the choice for either occasional users or full-time inspection professionals. Additional modules include CAD Programming and CAD Comparison . Make An Enquiry Aberlink 3D software is revolutionary. Feature Predict enables you to just take measurement points and the software automatically determines if you are measuring a Plane, Line or Circle feature. Move from feature to feature and the software predicts what you are measuring. As a component is measured a representation of it is built up on the screen. The user simply clicks on the measured features to call up dimensions exactly as they would appear on a drawing. Inspection reports can be in the form of fully dimensioned graphical representations as created on the screen, or tabulated reports in various formats that can show nominals, tolerances, errors, pass/fails, geometric tolerances etc. These reports can also be output as an Excel spreadsheet, First Article Inspection Reports FAIRs, Statistical Process Control Reports SPC.

Further reports are available to show the form of features (roundness, straightness etc.), hole or point positions, or complete batch results on one report. The user’s company name also appears on all outputs.

Every time a component is inspected, a programme for measuring subsequent components is automatically created. The software also calculates 'safe' moves between features, even when the probe is indexing – just another thing that the operator doesn’t have to worry about

Popular throughout the world and available in many languages, Aberlink’s revolutionary measurement software provides the user with a powerful, yet easy-to-use solution for inspection measurements. This not only increases component throughput but vastly reduces the learning period for new users.

Produce a CAD model from an Aberlink software STEP output in the standard software.

Optional Module Aberlink CAD Comparison software Ideal for complex non geometric shapes using IGES and STEP files.

Key Features Feature Inspection - Automatic measurement routines

- Powerful interactive graphics window

- Automatic feature recognition

- 2D and 3D inspection

- Geometric feature inspection

- Free form curve inspection

- DXF data import/export

- STEP and IGES export

- Feature construction

- Intelligent feature projection

- GD&T dimensions and tolerances

- Digital Read Out (DRO)

Programme Tools - Teach & repeat programming

- Drag and drop programme editor

- Run programs from any point

- Measure a subset of features

- Simple object-based programming

- No complex programming language

- Automated batch inspection

- Password protect programmes

- Automatic safety moves

- Feature replicator

Report Formats - Engineering drawing GD&T

- Simple PASS/FAIL

- Form plots

- Batch summary

- Tabulated reports

- Graphical fly-out labels

- Drag & drop reporting

- Real-time SPC

- Combine multiple views

- Export to Excel

- Historical data reporting

Supported Machines - Manual and CNC machines

- Coordinate Measuring Machines

- Vision measuring systems

- Portable arms

- Video inspection machines

- Profile projectors

Supported Probes - Manual probe heads

- Automated probe heads

- Rigid probes

- Motorised probe head

- Change racks

- Touch trigger probes

- Vision and video probes

CAD Comparison ModuleThe Aberlink CAD Comparison software module enhances Aberlink 3D with the capability to compare measured points to a CAD model. This may be the best way to measure complex geometries, or to inspect parts for which drawings do not exist.

Powerful alignment routines allow measurement points to be best-fitted to the model. Colour coded errors can then be displayed on the model to produce both graphical and tabulated reports that are extremely clear and very easy to understand.

Aberlink’s CAD comparison module allows the input of either STEP or IGES files as standard and allows reports to be exported as an Excel spreadsheet. It really does make measuring complex parts easy, whether on a manual or CNC CMM. Key Features CAD Formats - IGES and STEP import and export

- DXF export

- Re-scale Models

- Simple measurement of complex parts

Report Formats - On CAD fly-out labels

- Colour deviation whiskers

- Colour point markers

- Configurable colour options

- Combine multiple views

- Graphical and tabulated reports

- Export to Excel

Alignments - Point cloud best-fit

- Feature best-fit

- Best-fit constraints

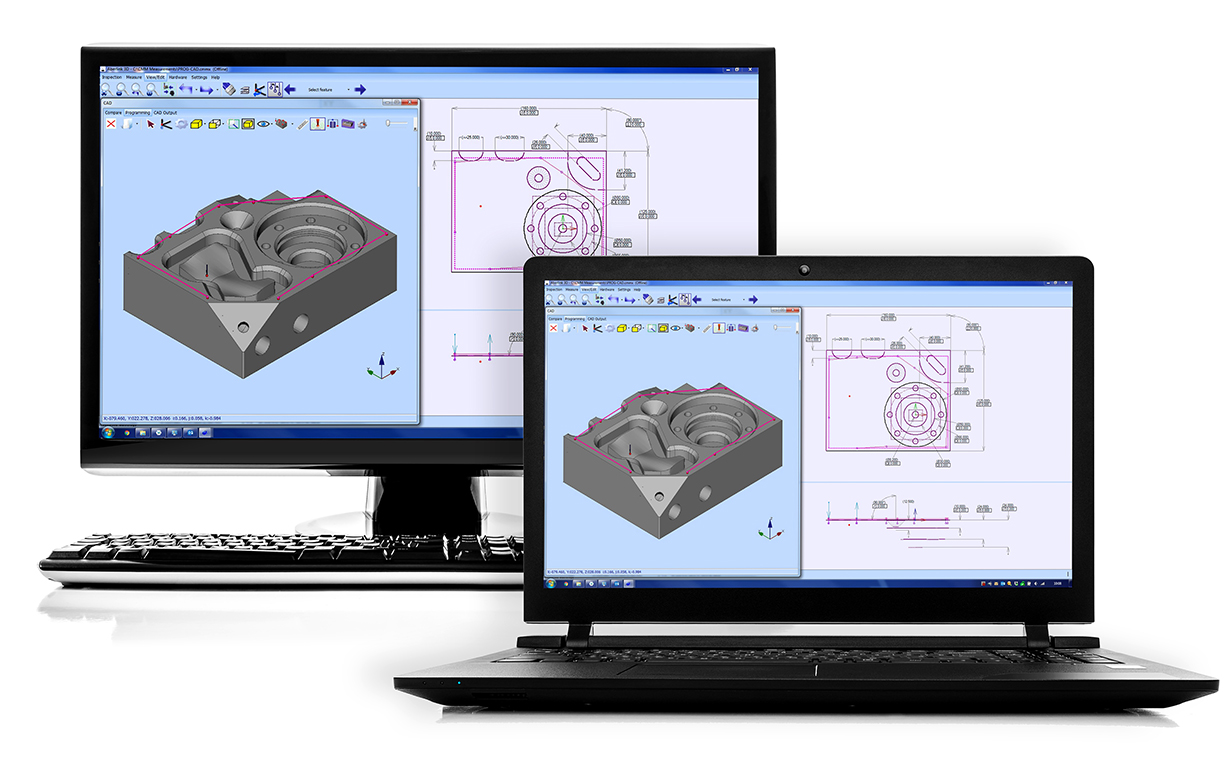

Make An Enquiry  CAD Programming ModuleAberlink’s CAD programming module can be used either on the CMM or offline as a virtual CMM.

For many years Aberlink 3D software has been setting the industry standard for both ease of use and speed of programming. However, until now this has been best done by using the teach-and-repeat method of programming when measuring a component. But what if you want to prepare the measurement programme before you even have the first component? Now the new CAD programming module, in true Aberlink fashion, allows the simplest programming possible from either an IGES or STEP CAD model.

If you can use Aberlink 3D software then you will already know how to use the CAD programming module – it couldn’t be easier. Rather than taking measurement points on a component, you can now just click on the surface of the model where you would like the points to be taken.

Feature Predict works in the same way as when measuring, for instance, if you click in four places on the same plane on the model, then the software will automatically create a Plane Measure unit with those four points in it. Then click on a different feature and it will automatically close the Plane window and look for another feature. If you click on a circular feature it will take just one click to produce a circle or two for a cylinder. Suddenly programming in Aberlink 3D just got even easier!

Make An Enquiry  ' CMM Retrofits From AberlinkImprove the performance and capability of your CMM Eventually, measurement software, probe systems and controller electronics become outdated by newer, faster, better systems. Our range of standard retrofits and upgrade kits will inject new life into your measuring machine. Aberlink's revolutionary measurement software provides you with a powerful, yet easy-to-use user interface. This substantially increases component through-put and vastly reduces the learning period of new users. Our latest generation of high quality machine controllers are compact, fantastic value-for-money and offer outstanding performance. Interpolated machine moves and advanced electronics will significantly reduce your current inspection cycle times whilst improving your CMM accuracy and repeatability. Aberlink's revolutionary measurement software provides a powerful, yet easy to use, state-of-the-art user interface. The software's unique interactive graphical interface offers a more satisfying user experience, substantially increases component through-put and vastly decreases the learning period of new users. Renishaw Probe System Upgrades from Aberlink such as an indexing head, fully motorised probe head or stylus change rack can dramatically increase through-put and reduce CMM set-up times, enabling you to measure more parts, faster and further reduce inspection bottle necks. Retrofit Features - Aberlink's revolutionary easy-to-use measurement software

- Windows-based CMM controller

- CMM power amplifier (optional)

- Probe system upgrade (optional)

- Installation and on-site verification test

- User training course

- Warranty

- Free telephone helpdesk support

- Free software upgrades - no maintenance fees or contracts

ABERLINK is a remarkble Metrology success story, having earned a global reputation for cost-effective Coordinate Measuring Machines and Optical Measuring Systems that are renowned internationally for their quality, accuracy, robustness, speed and above all for being extremely easy to use.

Make An Enquiry

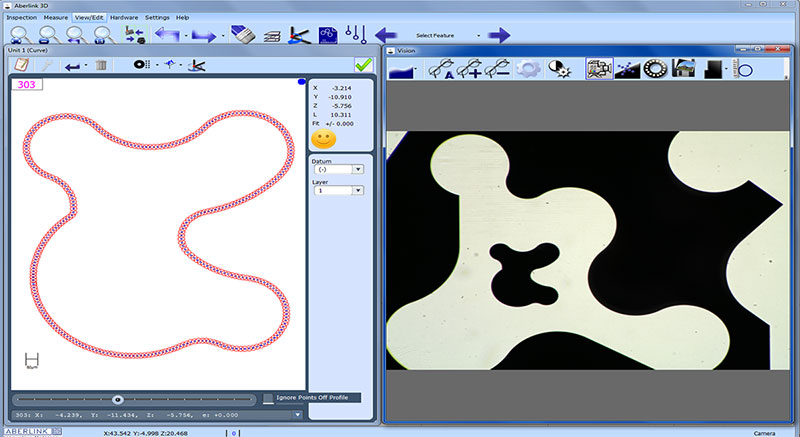

Vision Measurement Software

Measure geometric and complex shapes easily, features, scan profiles and inspect threads using high-accuracy edge detection and high-speed optical scanning. Simulate crosshairs and overlays, and control the camera and light settings, all from within the software. Download Aberlink Vision Brochure or make Contact Dimensions can either be called up by clicking on the measured features in the normal way, or alternatively measurement points can be best-fitted against a DXF file. As well as edge detection, use either full cross hairs or mouse cross hairs with other advanced tools available including "smart measure", centre line detection, an "all edge points" function, a "thread measure" tool and a "screen ruler" for quick measurements between any two points on the image.

The Aberlink Vision Software module enhances the capability of Aberlink 3D with a set of powerful vision measurement tools - use the same software with your touch probe and non-contact system. Featuring, fully automatic edge detection tools which can be used in both manual and CNC mode ensuring fast and repeatable results without relying on the skill of the operator.

Make Enquiry  Advanced USB 2 Camera/Vision SystemAberlink's CCD camera system offers non-contact measurement on a CMM . A telecentric lens gives distortion-free images on the monitor. Automatic edge detection allows the camera to be used in manual or CNC mode. The lens is adjustable so that working distance can be varied from 130mm to infinity. At 400mm the field of view is a huge 35mm. A fully controllable 16 LED light ring is built into the camera and a clever magnetic, kinematic design allows the probe and camera to be changed in just seconds. Back Lighting when using a Camera System has always been difficult on a CMM, as the base of the machine is solid. Whilst it is possible to use a light box, this is cumbersome, limits the weight of the component that can be measured and is not controllable within the software. However, Aberlink have come up with a brilliant invention to make back lighting of a component on a CMM both simple and controllable: From now on the light ring on our Camera System contain alternate white and UV LEDs. The white LEDs provide surface illumination in the normal manner, while the UV LEDs are used to provide back lighting. The component to be measured is placed on an Aberlink white backplate which sits flat on the granite table. When back lighting is required the component is illuminated with UV light. Any light striking the surface of the component is reflected, and because it is UV is invisible to the camera. However, any light, which passes by the component and strikes the white plate fluoresces and therefore becomes visible. The effect of this is that an extremely sharp silhouette of the component is produced, as it is now being lit from underneath……and all this at NO EXTRA COST. This can cover the whole measurement area of the CMM. It consists of ‘special’ reflective paper underneath a sheet of glass and housed in a frame. By lifting the component above the reflective paper we also ensure that the reflected light is closer to being collimated and the shadowing effect around the edges is effectively eliminated. The patent for this technology has been filed, once again with help from our friends at Renishaw. Hopefully having their name on the patent will add weight to deter any companies from ‘borrowing’ another one of Marcus’ clever ideas!

Backlighting solution for components and parts requiring additional illumination.

The CMM collimated light enables backlight illumination of 3D or turned components. A single-LED collimated light features a compact, lightweight design which is perfect for the Axiom too range of CMMs and is fully programmable and controllable within Aberlink vision software. Available in 120mm and 68mm diameters. Aberlink Collimated LightFeatures - 68 or 120mm diameter field of view

- Compact, lightweight design

- Fully controllable through Aberlink 3D vision software

- Easily replaceable top glass

For further information about the Aberlink CMM collimated light please email sales@purduemetrology.co.uk Make An Enquiry CMM Probe and Probe Head OptionsEvery Aberlink CMM fully supports the range of probe heads and both touch trigger and scanning probes supplied by Renishaw. The following are common options. Probe/Head Integral Probe Index Motion Maximum Length Index Resolution Index Positions Repeatable Indexing Repeatable StylusChanging Probe/Head

TP8 Integral Probe

Yes Index Motion

Manual Maximum Length

105mm Index Resolution

Infinite Index Positions

Infinite Repeatable Indexing

No Repeatable StylusChanging

No Probe/Head

MH20i Integral Probe

Yes Index Motion

Manual Maximum Length

150mm Index Resolution

15° Index Positions

168 Repeatable Indexing

Yes Repeatable StylusChanging

Yes Probe/Head

RTP20 Integral Probe

Yes Index Motion

Automated Maximum Length

168mm Index Resolution

15° Index Positions

168 Repeatable Indexing

Yes Repeatable StylusChanging

Yes Probe/Head

PH10T Integral Probe

No Index Motion

Motorised Maximum Length

450mm Index Resolution

7.5° Index Positions

720 Repeatable Indexing

Yes Repeatable StylusChanging

Yes Probe/Head

PH20 Integral Probe

Yes Index Motion

Motorised Maximum Length

168mm Index Resolution

Infinite Index Positions

Infinite Repeatable Indexing

Yes Repeatable StylusChanging

Yes Probe/Head

PH6M Integral Probe

No Index Motion

No Maximum Length

450mm Index Resolution

No Index Positions

No Repeatable Indexing

No Repeatable StylusChanging

Yes Probe/Head

PH10M Integral Probe

No Index Motion

Motorised Maximum Length

450mm Index Resolution

7.5° Index Positions

720 Repeatable Indexing

Yes Repeatable StylusChanging

Yes The TP8 probe offers an entry level option for customers that require infrequent indexing of the probe and no indexing during the running of a measurement programme. The TP8 is supplied with two knuckle joints to allow infinite alignment of the probe to the feature being measured, but this alignment is non repeatable, meaning that the stylus will need to be requalified following each index. The TP8 probe accepts the M3 range of styli. The MH20i probe offers repeatable manual indexing of the probe head from 0° to 90° in the A axis and through 360° in the B axis, in 15° increments. Ideal for manual CMMs, it can also be used on CNC models, but will require intervention from the operator whenever indexing is required. The MH20i uses a TP20 stylus module, which in turn accepts the M2 range of styli. The RTP20 probe offers a cost effective solution for customers that require automatic indexing on CNC machines. Modelled on the MH20i body, the RTP20 uses the CNC motion of the CMM to position itself using a post mounted to the bed of the machine. Like the MH20i it is able to index from 0° to 90° in the A axis and through 360° in the B axis, in 15° increments and uses a TP20 stylus module, which in turn accepts the M2 range of styli. The RTP20 is also fully compatible with the MCR20 change rack to provide an option that provides both automatic stylus changing as well as automatic indexing. The PH10T is a fully motorised probe head that offers immediate indexing from 0° to 105° in the A axis and through 360° in the B axis, in 7.5° increments. This probe head should be used by customers requiring frequent indexing or when more precise alignment to the features being measured is required. Like the PH10T probe head, the PH10M is also a fully motorised probe head that offers immediate indexing from 0° to 105° in the A axis and through 360° in the B axis, in 7.5° increments. The M head, however, incorporates an autojoint with multiwire capability, which is necessary for the SP25M scanning probe. The PH10M probe head can also be fitted with either TP20 or TP200 probes and should be chosen in preference to the PH10T when using these probes if the future use of a scanning technology may be required. This head provides a fixed autojoint for when an SP25M scanning probe is required without the requirement for indexing. Compatible with the complete Renishaw multiwire probe range and standard probes with autojoint adaptors and extension bars. Incorporating the latest 5-axis technology, the PH20 head offers infinite indexing to assist with alignment to any feature being measured at any angle up to 120°. The probe is able to perform 'head touches', where it flicks the stylus on to the surface of the component being measured, while the machine remains stationary. This increases both the speed of measuring and accuracy achievable. Please note that if selecting the PH20 head, then the machine would also have to be fitted with a Renishaw CMM controller. The PH20 uses TP20 stylus modules, which in turn accept the M2 range of styli. SP25M Scanning ProbeThe SP25M scanning probe uses an isolated optical metrology transducer system to enable extremely accurate measurements to be taken with the stylus in continuous contact with the feature being inspected. This enables more data to be taken, which is important when form is critical. A range of modules are available for the SP25M to provide optimised scanning performance using M3 styli up to 400mm long.

Aberlink Video - Aberlink Innovative Metrology LLP - Company Profile

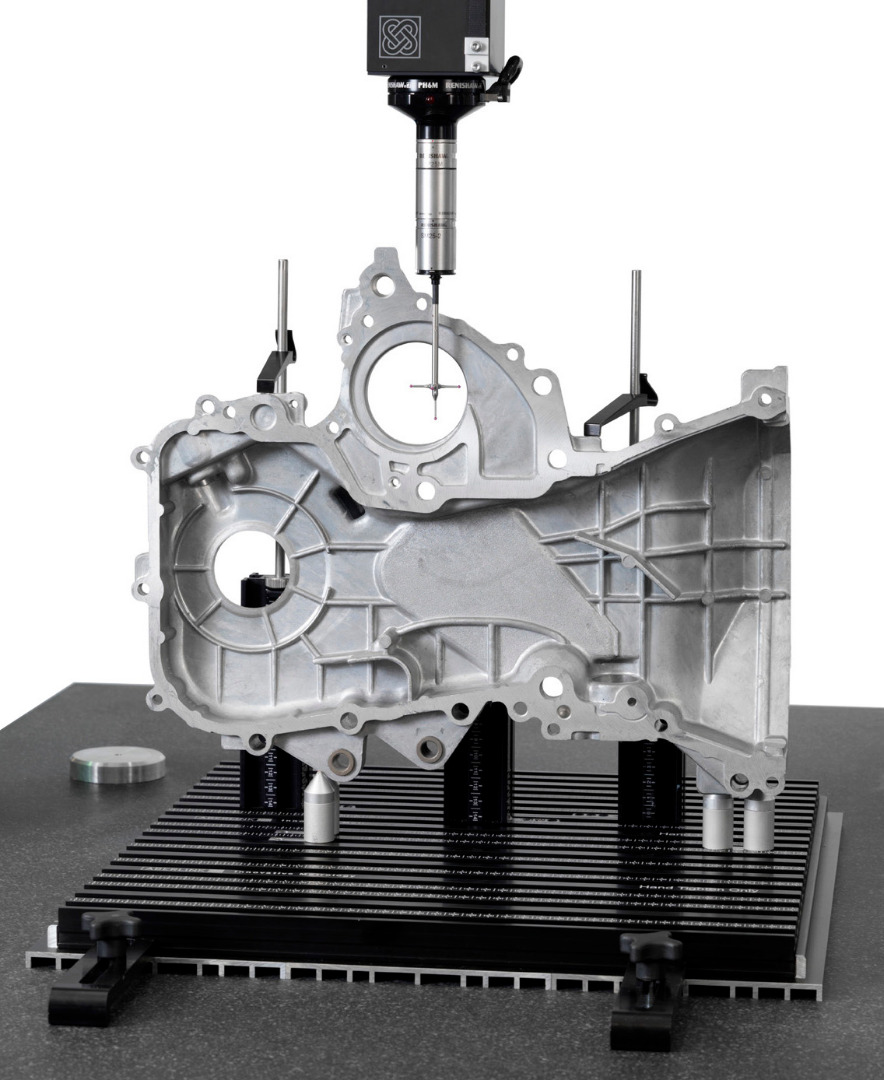

Make An Enquiry   CMM FixturingThe new generation of infinitely adjustable CMM fixture kits offer significant advantages over traditional fixture systems. Patent pending T-slot and T-nut technology provides infinite adjustment of the fixture components in multiple directions. Clamps, locators and supports can be placed in exactly the right position to suit the part. Greater flexibility results in less complicated designs, fixtures are easier to assemble and completed in less time.

Fixture mountings incorporate one or more t-slot. The slot receives a sliding t-nut which is used to secure the fixture components in place. For rapid repeat set-ups, fixture components can be removed and replaced without disturbing the t-nut while laser engraved scales and alpha markings facilitate more precise builds.

Any number of designs can be created from a single fixture kit. Over one hundred high quality parts manufactured from anodised aluminium and stainless steel are supplied in a compartmented storage case. All types of prismatic and free form parts can be held and supported correctly during measurement. These are substantial kits and represent great value fo money.

FixLogic Kits with base plates - provide a flexible, quick and reliable method for mounting parts within the measurement vloume of the CMM.

300 x 300 mm base plate and kit £1,300 plus vat

450 x 450 mm base plate and kit £1,375 plus vat

600 x 450 mm base plate and kit £1,450 plus vat

Download brochure listing individual items FixLogic

CMM Fixture Kit video (example 1) - https://www.youtube.com/watch?v=y9d7uIG4Rdk CMM Fixture Kit video (example 2) - https://www.youtube.com/watch?v=EA5n89Rab98 CMM Fixture Kit video (example 3) - https://www.youtube.com/watch?v=F_jG2Gkllf4 We also offer Bespoke CMM fixtures designed for inspection of high volume components or difficult to hold components, please contact us to discuss your requirement.

Make An Enquiry   CMM Enclosures Enclosures for Co-ordinate Measuring Machines (CMMs), machine tools, gauging fixtures etc

Mobile and stationary work benches for example for meassuring arms

Conveyors and many other applications.

Enclosures can be designed to fit the machine or be supplied as a room with space in front or around the machine for the operator to work in.

Enclosures for CMMs, Optical Machines, Measurement Gauging Systems, Machine Tools, Conveyors etc

The most frequent influence on accuracy in CMMs is temperature and worse still fluctuations in temperature, Enclosures protect CMMs from shop-floor temperature variations.

Enclosures to protect your CMM, Optical Machine or other Measurement System from the elements in a busy shop-floor environment help reduce temperature fluctuations. The frame is designed using Bosch aluminium extruded profile which provides robust, hardwearing construction. The enclosure is designed to fit closely to the equipment, thereby maintaining the smallest footprint. Both standard designs and bespoke solutions to suit your requirements.

The systems include positive air pressure to minimize the chance of any air-born particles from contacting the equipment during component loading/unloading. It is important to consider access for component loading and to any pneumatic or electrical equipment for the changing of any filters or venting any drain valves. Any electrical cables running from the Measurement System, controller and PC, may require consideration. Torus can also include access panels for removal when servicing the Measurement System, these panels can be easily removed and handles supplied to assist this operation.

Options:

Door - Hinged, Bi-folding, Sliding, Counter-balanced

Brush strip cable access situated to suit customer specification.

Panel colour, available in a range of customer specified colours.

Positive air pressure - To keep the equipment free from dust and dirt.

Lighting - Internal lighting system that will ensure the user can observe the measurement process.

Air conditioning - The temperature can normally be controlled within +/- 2ºC.

Traffic light system - Warning lights and audible alarms

Interlock system - To suit customer specification or health & safety requirements

Floor mounted - Freestanding or secured

Maintenance access panels - Access doors to any pneumatic equipment

Service access panels - Easy access panels for removal when serving the measuring equipment

To ensure our enclosure solution will satisfy all aspects of your operation, a site survey is offered. In addition to the enclosure, PC/ operator workstations, fixture / work-holding and storage units are offered to complement your measurement solution.

Air Conditioning Option

+/- 2C guaranteed temperature

24 hr Internal & External Average

Temperature Monitoring

For more information and a detailed quote based on your requirements, please contact us:

Make An Enquiry

Fast turn around Contract Inspection service for Aberlink and non-Aberlink customers at very competitive rates. We can measure your parts when your own inspection resources are over stretched.

We can provide a fully trained Aberlink applications engineer to measure your parts, or if you prefer you can simply hire the equipment and measure the parts yourself.

We can now also offer on-site sub contact part programming, subject to availability. Inspection Services- First-off Inspection (ISIR)

- Batch Inspection

- Machine capability

- Process capability

- Statistical Process Control (SPC)

- Fixture verification and calibration

- Collection and return service

- Rapid turn around

Measurement Equipment- High accurate coordinate measuring machines

- Non-contact inspection video system

- Manual, automated and motorised probe heads

- Probe and stylus change racks

- Maximum component size 3m

- Maximum component weight 1000kg

If you are in the UK and would like more information about Contract Inspection please call 07887 691129 or email: mike@purduemetrology.co.uk CMM RentalTake delivery of a Coordinate Measuring Machine without investing capital.

Rent any one of Aberlink's range of touch trigger probe or vision systems for a fraction of the cost of a new machine. Manual and CNC machines, with axis travels from 400mm to 3000mm, are usually available on a short delivery. If you decide to purchase the system during the rental period, 80% of rental payments will count toward the purchase.

The regular monthly rental cost is 1/30th of the purchase cost, installation is charged with the initial payment, three payments are required on installation followed by two months with no payment required, from then on it's the regular rental. Please request a CMM rental quotation. Contract InspectionAberlink can measure your parts when your own inspection resources are over stretched. Providing a fast turn around Contract Inspection service for Aberlink and non-Aberlink customers at very competitive rates.

Inspection Services - First-off Inspection (ISIR)

- Batch Inspection

- Machine capability

- Process capability

- Statistical Process Control (SPC)

- Fixture verification and calibration

- Collection and return service

- Rapid turn around

Measurement Equipment - High accurate coordinate measuring machines

- Non-contact inspection video system

- Manual, automated and motorised probe heads

- Probe and stylus change racks

- Maximum component size 3m

- Maximum component weight 1000kg

We can provide a fully trained Aberlink Applications Engineer to measure your parts, or if you prefer you can simply hire the equipment and measure the parts yourself.

If you are in the UK and would like more information about Contract Inspection please call 01256 881179 or email mike@purduemetrology.co.uk Make An Enquiry  New portable workstation for measuring armsBuilt using aluminium extruded profile, Torus Automations’ new portable workstation for measuring arms, provides a robust, hardwearing construction, with a flexible ergonomic design. The design can be custom made to suit your requirements.

The benefits of Tours’ new portable workstation for measuring arms are efficient and effective measuring by locating all aspects of the measuring equipment and fixturing in one handy workstation which can be located where suitable due to it’s portable design. Key Features & Options- Overall Size to suit customer requirements

- Optional hinged table extensions

- Flat Pack shipping for self assembly

- Extension Sockets – 4 -13A 230v and 110v

- In built levelling device

- Drawers with foam inserts for fixture elements

- Safe working loads of up to 250kgs, load bearing capacity

- Drawer partitioning

- Scratch-proof Trespa shelf with support struts

- Brush strip at rear for cable access

- Foamex panels – available in a variety of colours

- Closed profile on external faces

- Lockable cupboards

- Easily adaptable and customisable to suit customer requirements

- Fixture plate options (drilled/tapped/steel/aluminium

- Laptop platform with variable positioning

- Mobile unit with swivel wheels with brakes for locking and/or Jacking points with 100kgs weight capacity.

Make An Enquiry Used re-furbished Coordinate Measuring Machines We often have used CMMs and ex-showroom CMMs for sale please contact us for more information or to arrange a demonstration

Make An Enquiry  What is a CMM? Do I need a CMM?The most common use of a CMM (Coordinate Measuring Machins) is to test the accuracy of a manufactured part against its original design to ensure stringent quality requirements are met and adhered to.

A CMM can measure size, position and form of features such as Planes, Lines, Points, Circles, Cylinders, Spheres as well as free forms 2D curves and complex 3D forms. The reporting capability and repeatable nature of the measurements are exceptional when compared with conventional inspection and measurement methods. They save time and man power.

A classic, bridge-style Coordinate Measuring Machine (CMM) accurately measures the geometry of an object along X, Y and Z axes using a touch-trigger, scanning or vision probe to take a series of precise points on the surface of an object. CMMs can be made from a wide variety of materials, however a combination of granite and aluminium has been widely adopted by the industry due to its stiffness to weight ratio and allowing the constructed materials to be thermally dynamic. Changes in ambient temperatures and thus expansion or contractions of the machine’s materials are monitored and compensated for in the user software. The probes position can be manually controlled or, automatically (CNC) through the use of a computer. The position is defined using a reference sphere in the X-Y-Z coordinate system. CMMs also allow the probe angle to be controlled to enable the measurement of complex surfaces that may otherwise be unreachable. Why do I need a CMM?Traditional handheld inspection methods have their limitations and rely heavily on the skill of the personnel inspecting the parts. Incorrectly manufactured parts can go undetected and get dispatched to your customer. In addition, as manufacturing design becomes more refined, parts are made more complex meaning some features can only be accurately measured with a CMM. With the need to speed-up and streamline inspection processes, this is where CMM inspection offers accurate, repeatable results in a fraction of the time, all the while meeting ever-increasing customer demands. The bottom-line - a CMM will save your company time and money and will enable your company to tender for more profitable work. Opt in for an informative product quarterly email. Unsubscribe at any time. Opt in |