Video 2D/3D Measuring MachinesVideo, Optical based non contact coordinate measuring systems, 2D Shaft Scan - the choice is vast, please enquire (or call) to discuss your requirement.

Other CMMs and MultiSensor Video Measuring machines with touch and laser options like the ScopeCheck or CMMs with a camera option are worth comparing.  2D non contact Inspection system, manual £11,340 or CNC £16,290 (+vat).

Aberlink's very competitively priced modern alternative to a shadowgraph projector with powerful software and now with collimated light for cylindrical parts. A large measuring area of 400 X 300 mm and a motorised deep Z focus distance of 125 mm allows measurement of components of much larger dimensions than most projectors.  The KineMic KMR-FOV-M3 video microscope includes a color digital video camera, fixed magnification telecentric lens, 21.5" all-in-one-touchscreen PC, MetLogix M3 software with Digital Comparator (DC) feature, LED backlight and ringlight. M3 models offer Field-Of-View measurement, powerful image processing, DXF imports for direct comparison to the work piece. Stand it upright or lay it on it's back for a horizontal machine, incredibly versatile. Rapidly inspect and measure a single feature, an entire part, or multiple parts up to 3.65 x 3" (92.7 mm x 76.2 mm) with the HVR-Flip's large FOV. MetLogix™ M3 software allows for easy one-touch feature measurement and auto-detect part recognition. The MarShaft SCOPE 250 plus is a modern, high performance, small capacity, competitively priced shaft measuring machine. Simple, fast, accurate video measuring system for measuring shaft, diameters, lengths, radii, chamfer, grooves, tapers and much more, It enables fast, precise and fully automatic measurement of rotationally symmetrical workpieces in production, cutting time invested in the measuring process and reducing waste. The only video measuring system to incorporate an ergonomic measuring microscope. Previously difficult-to-view samples can now be measured and inspected on the same system, in the same routine, by the same operator. Swift PRO Duo provides fast and accurate measurement of both routine and complex precision parts. Vision Eng LVC400Large capacity vision and touch measuring machine 400 x 300 x 200 mm. Has the power and flexibility to meet the most demanding measurement requirements and suits industry applications including precision machining, casting, plastic mouldings, electronics and medical device. Automated Measurements in 3 Axes - High accuracy - Competitive price

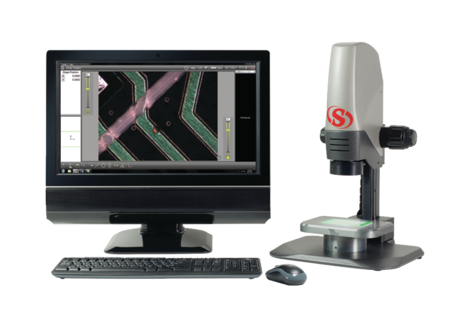

Starrett AVR300

These Starrett systems are versatile CNC video and touch based coordinate measurement machines, ideal for the measurement of CNC machined parts, mouldings in quality assurance, shop floor and inspection labs, as well as manufacturing, assembly and research facilities. Starrett HDVThe innovative new HDV Horizontal Digital Video comparator combines the best features of a horizontal optical comparator and a vision metrology system, ideal for measuring flat parts, machined or moulded parts and cylindrical or turned parts, quickly, simply and accurately. Accuracy down to 1.1 micron.

This series of Video CMMs is ideal for small measurement ranges that require high accuracy. VideoCheck S machines use the Werth image processing sensor with telecentric Werth Zoom and MultiRing. They can be equipped with a wide selection of additional optical and tactile sensors, including the patented Werth Fiber Probe. See through your components and take accurate measurements in 3D. Ideal for assembled components with multiple materials, connectors, plastic mouldings etc.

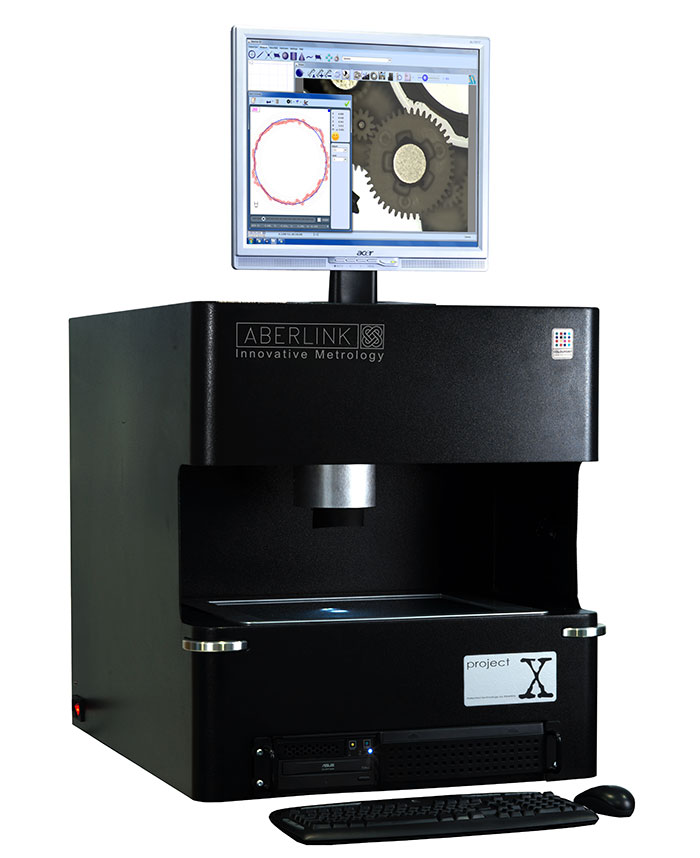

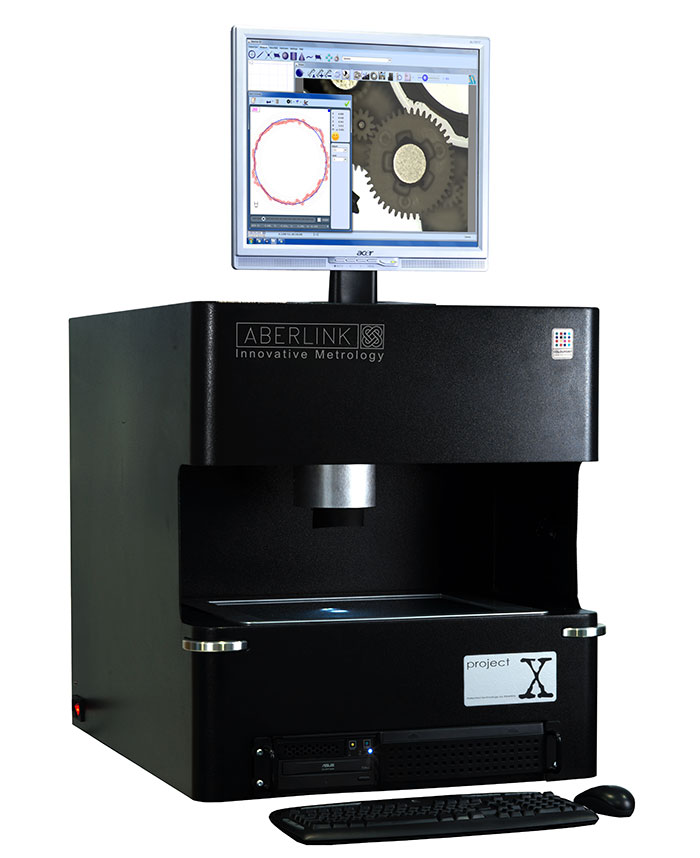

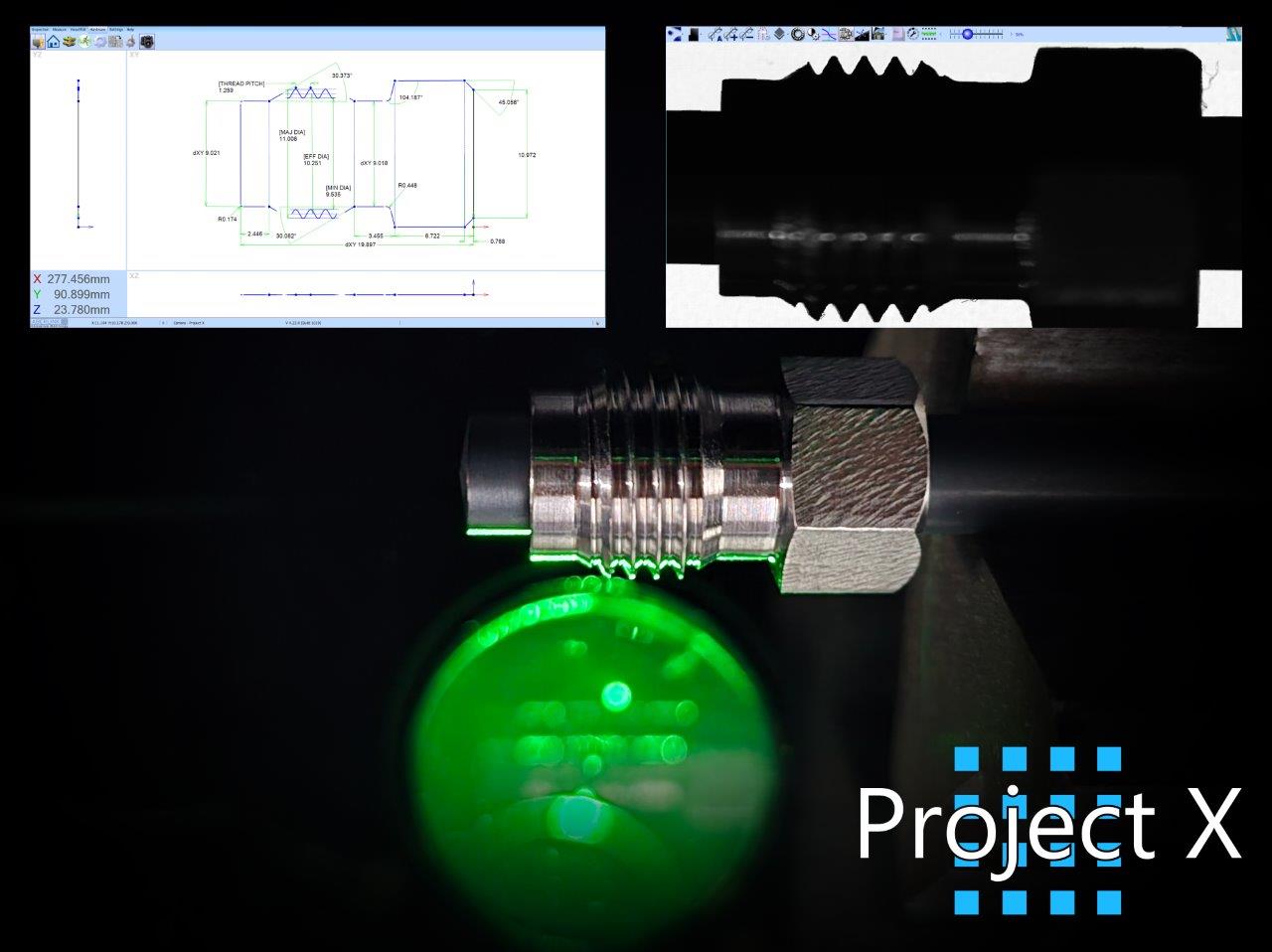

X-ray Computed Tomography Coordinate Measuring Machines CMM reduce first article Inspection time from a few days using classical metrology to a few minutes. eviXscan 3D FinePrecision ScanningThe FinePrecision 3D scanner is perfect as a measuring tool for precision mechanics, especially: production of turbine blades, microcircuits, small injection parts and precise numerically processed parts. FinePrecision is also used in scanning implants, in prosthetics, and watchmaking and jewellery. The precision of the scanner also allows it to be used to optimize the 3D printing process (larger systems available).   Aberlink's Project X with collimated back light2D non contact Inspection system, manual or CNC. Aberlink's powerful and very competitively priced modern alternative to a vertical light path projector, with Aberlink's popular award winning software for 2D vision. Video measurerment using patented "Colour Map" scale technology, Project X moves the camera over the component rather than the component under the camera, thus avoiding the need to secure the part. A large measuring area of 400 X 300 mm and a motorised deep Z focus distance of 125 mm allows measurement of components of much larger dimensions than most projectors, shadowgraphs and optical comparitors. All parameters used for the edge detection tools including programmable LED light source can be adjusted during any measurement and the results seen live on the flat screen monitor and automatically stored as part of the program. Geometric measurements can be picked off with a mouse or compared to a DXF file. Collimated under stage lightProject X, has been updated with a new, green light, collimated under stage light. This significant improvement to the backlight illumination of deep cross-section or turned components creates a crisp silhouette of the profile being measured. This clear contrast between light and dark ensures the automatic edge detection results in even better accuracy and repeatability of the part/features being measured.

Get in Touch for more information or a demonstration

- Aberlink's easy-to-use vision measurement software

- Fully automated CNC, or manual, non-contact inspection for small and delicate parts

- Small enough to be positioned on the production workbench

- Fully programmable digital zoom, no need to change lenses

- High speed optical scanning - up to 5000 points/second

- Powerful edge detection tools for maximum accuracy

- Directional overhead lights and back light provide profile and surface feature inspection

- Measures accurately even when the feature is not in focus

- Collimated back light, suitable for turned components

- Aberlink vision measurement software for non-contact inspection

- Windows based controller and peripherals

- Optional workbench

- Aberlink 2048x1536 pixel colour camera and telecentric lens

- Programmable colimated back light and overhead LED ring-light

- User training course - up to 4 trainees and software user guide

- 12 months full parts and labour warranty

- Free telephone helpdesk support

- Free software upgrades - no maintenance fees or contracts

All for an amazing £11,340 plus vat for the manual version including training, or £16,290 plus vat for CNC

Installation and on site calibration £1,450 plus vat.

Make An Enquiry

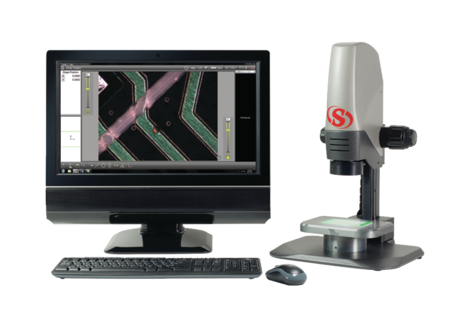

StarrettKineMic KMR-FOV-M3 Video MicroscopeThe KineMic KMR-FOV-M3 video microscope includes a color digital video camera, fixed magnification telecentric lens, 21.5" all-in-one-touchscreen PC, MetLogix M3 software with Digital Comparator (DC) feature, LED backlight and ringlight. These affordable video based inspection and measurement systems are ideal for receiving inspection, quality assurance, training, manufacturing assembly, research and documentation - wherever easy setup and operation is required. M3 models offer Field-Of-View measurement, powerful image processing, DXF imports for direct comparison to the work piece.

Make Enquiry

Brochure pdf - https://www.starrett.com/vdoc/KineMic%20KMR%20(Bulletin%20976)

Key Features Optics: 6 telecentric lenses CCD Sensor / Resolution: 2.02 Mpixel Camera Interface: USB Cable: Computer: All in one PC Software: MetLogix M3 Video Screen: 21.5" Allin one PC Screen Resolution:1920 x 1080 Lens Magnification: .30x, .50x, .80x, 1.0x, 2.0x, 4.0x Screen Magnification: 13x to 178x Field of View (X-Axis): 1.8 to 24 mm X-Y Stage Motion (inch): None X-Y Stage Motion (mm): None Metrology Means: M3 FOV Software Measurement Resolution: Up to 2um Measurement Accuracy: Up to +/- 2.5um Basic Stand: Standard LED Back Light: Standard LED Ring Light: Standard Lighting Control: Via M3 Software Video Inspection: Yes Basic Dimensions: VED Geometric Constructs: Yes Image Annotation: Yes Image Archiving: Yes Video Edge Detection: Yes

Make An Enquiry

Starrett HVR100-FLIP FOV Digital Video SystemRapidly inspect and measure a single feature, an entire part, or multiple parts up to 3.65 x 3" (92.7 mm x 76.2 mm) with the HVR-Flip's large FOV. MetLogix™ M3 software allows for easy one-touch feature measurement and auto-detect part recognition.

Features DXF import and export, graphic based "Part View" constructions and more. Optional software modules are available for profile fitting, wire insulation and thread measurement.

The HVR-Flip from Starrett is the latest in a line of video-based measurement systems. The HVR-Flip has the unique characteristic of being used in either a vertical or horizontal format offering tremendous versatility and value.

Make Enquiry

Video - https://www.youtube.com/watch?v=ITqupFIgRtA Key Features - Rapidly measure parts up to 3.65 x 3"

- Working distance of 10"

- Measure a single feature, an entire part, or multiple parts

- MetLogix™ M3 software allows for easy one-touch feature measurement

- Auto-detect part recognition

- DXF Import - Electronic overlay for quick part comparison

- Export features to DXF

- Compare complex profiles with discreet data points and comparison to CAD

- Graphic based "Part View" constructions

- Geometric tolerancing

- Flexible report content and formatting

- Multi-language support

- System can be easily converted from a vertical format to a horizontal format measuring system

- Large FOV

If you have any questions, or would like to hear more about this metrology instrument feel free to Contact usPlease note that the computer supplied may vary slightly from the one in the above images Make An Enquiry  ??????? Starrett AVR-FOV CNC Vision machineThe New AVR-FOV Series is the next evolution to the Starrett bench top vision metrology family, ideal for automated measurement and comparison to CAD files. The AVR-FOV features dedicated 0.14x telecentric optics for instant Field of View imaging and measurement, without need for complicated calculations. The systems runs on user friendly M3 software with image processing and part recognition programming. The AVR-FOV is optimised for fast, operator led inspection routines featuring auto CAD comparison and easy import and export features.

Ask a question or Make Enquiry

Features and Benefits - Bench top with granite base

- Metlogix M3 Software with video edge detection

- Field of View measurements integrated with stage motion

- 24" Touchscreen PC Display

- Digital Video Camera: 1.3 MP colour (2.0 MP with telecentric)

Accessories and Options- Quadrant LED surface Illumination or Zoom Optics

- DXF/FOV option pack for automatic comparison to CAD Designs

- Renishaw Scales for 0.1µm (X-Y-Z Axis)

- Renishaw touch probe kit with 2 or 4 bay probe rack

- Part fixtures and work holding devices

- Thread measurement software module

- CNC rotary axis fixture

Specification- Dedicated 0.14x telecentric optics

- X - Y Travel: 300mm x 200mm

- Z Travel: 200mm with 2.0x auxiliary lens

- Measurement resolution: up to 3µm

- Measurement accuracy (X-Y): up to ±3 + 5L/1000 µm

- Measurement accuracy (Z): up to ±3.5 + 5L/1000 µm

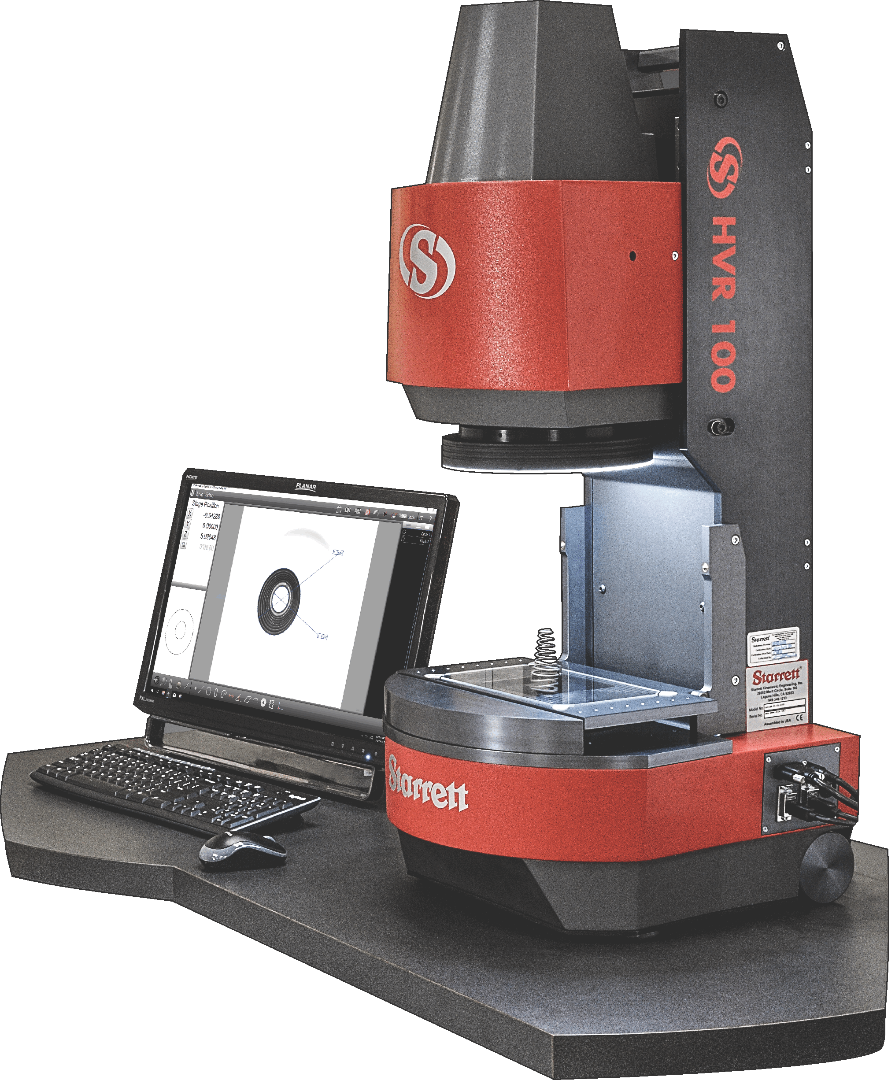

Starrett AVR300 small measuring machineThese Starrett systems are versatile CNC video and touch based coordinate measurement machines, ideal for the measurement of CNC machined parts, mouldings in quality assurance, shop floor and inspection labs, as well as manufacturing, assembly and research facilities.

Video measurement made easy with the CNC Vision Measuring System for easy measurement of complex parts. This system has grown in popularity as customer awareness of it's versatility and performance to price ratio. The AVR CNC systems are powerful automated video measuring systems, ideal for repetitive measurements and automatic comparison of data to CAD files as well as geometric tabulated and graphical reports. The AVR is controlled by a powerful MetLogix software system, features 6.5:1 (optional 12:1) zoom optics and several LED illumination options. There is also the option of a Renishaw touch probe. A manual version is available called the MVR300 and both AVR and MVR are available in a smaller 200 mm size at a lower cost. These compact bench top systems are precise and powerful. Key Features - Bench top system with Granite base

- Full CNC operation

- Z axis measuring as standard

- Video Edge Detection (VED)

- LED surface ring and transmitted illumination

- X-Y-Z Travel 300 x 300 x 200mm

- X-Y Accuracy (µm): E2 = 1.9 µm + 5L/1000

- Z Accuracy (µm): E1 = 2.5 µm + 5L/1000

- M3 Software control

- 21" Touchscreen PC display

- 1 MP Colour Digital Camera as Standard. 2MP with Telecentric

If you have any questions, or would like to hear more about this metrology instrument feel free to Contact us

Make An Enquiry

LF713 Large Format CNC Vision System

The LF Series Vision Systems from Starrett are the most advanced CNC vision systems we offer, in terms of both speed and accuracy. The LF outperforms the AV300 technically and also features the option of an expanded X-Y-Z measuring range up to 1270 x 915 x 200 mm.

Versatile, accurate and incredibly fast, this system will provide consistently accurate and reliable measurements.

Designed for large parts and CNC operation this CNC vision system is ideal for quality assurance, inspection labs, manufacturing, assembly and research facilities.

LF713 floor standing metrology system offers 28" x 24" x 8" (710 mm x 605 mm x 200 mm) of travel, a massive granite base and granite bridge, air bearings and high speed linear motors for the X and Y axes, your choice of powerful MetLogix or Quadra-Check software control systems, LED illumination, video edge detection (VED) with a hi-resolution digital color video camera and 6.5:1 or 12:1 zoom optics and the capability to add optional touch and laser probes. Larger travel systems are available upon request. These systems are multi-purpose CNC measurement systems, ideal for quality assurance, inspection labs, manufacturing, assembly and research facilities. This versatile floor standing system is fast, precise and powerful. Key Features - X-Y-Z measuring range from 300 x 300 x 200 mm to 1270 x 915 x200.

- X-Y-Z resolution of 0.1µm

- X-Y-Z accuracy of 1.5 µm + 5L/1000

- Air bearings and linear motors for X and Y axes

- 1/3" CCD color video camera

- 12.0:1 Navitar zoom optics

- Metronics QC5300 CNC 3D multi-sensor metrology software

Have a question? Or if you just want more information Contact us, we would love to hear from you.

Accessories (options)- Reinshaw touch probes

- Touch probe changing rack

- Optimet laser probe

- 100mm CNC rotary stage

- LED dark-field quadrant illumination

- Parts holding fixtures

Make An Enquiry

SWIFT PRO DUODual Video and Optical Measuring System Two inspection and measurement systems in one! Swift PRO Duo is the only video measuring system to incorporate an ergonomic measuring microscope.

Previously difficult-to-view samples can now be measured and inspected on the same system, in the same routine, by the same operator. Swift PRO Duo provides fast and accurate measurement of both routine and complex precision parts. With a rich suite of measurement and reporting features, it is the right measurement tool for a broad range of applications, from electronics and aerospace to automotive, plastics and medical device manufacturing.

VISION SWIFT PRO DUO DEMONSTRATION VIDEO

Request brochure and prices

Key Features - Optical Microscope and video measure system in one

- Up to 200mm x 100 mm measurement stage, 5 micron stage accuracy

- Advanced and robust measuring system in a compact size

- Designed especially for toolmakers and shopfloor operators

- Take accurate measurements in seconds, with no need for pre-programming

- Z-axis variant for height measurement

- Patented optical ergonomic microscope offers high resolution surface inspection

- Ideal for use on the shop floor and in the QC Lab

Make An Enquiry  VISION LVC400 Touch and vision measuring machineLarge Capacity CNC Video Measurement System Automated Measurements in 3 Axes - High accuracy - Competitive priceLengthy measurement routines are often a big problem for manufacturers. Reducing measurement time, without compromising product quality is a critical factor in the continuous improvement of the manufacturing process. LVC400 has the power and flexibility to meet the most demanding measurement requirements and suits industry applications including precision machining, casting, plastic mouldings, electronics and medical device.

VISION LVC400 DEMONSTRATION VIDEO Request brochure and prices

Key Features: - Measure components up to 400mm x 300mm x 200mm

- Great video image with 5MP USB3.0 camera

- Motorised zoom lens for automatically changing magnification in measurement routines.

- Intuitive M3 software maintains ease of use despite advanced functionality of the system.

- Granite base for extra stability and measuring accuracy.

- Touch probe option for measuring complex features and 3D forms, such as cylinders, cones and spheres.

- Ideal for a wide range of applications including precision engineering, casting, plastic moulding, electonics and medical devices manufacture.

Make An Enquiry

Venture XT camera based CMMVision CNC non contact optical CMM with Renishaw touch probe option

Greatly improved performance and software functions. A huge update to the range and it’s capability ensures that customers get a wide range of product options to help overcome measurement issues. The Venture XT is a newly styled vision system that includes an extended 200mm measuring range in the Z axis and a new column design with integral Z axis counter balance. In addition there are faster X-Y axis drives, a touch screen, greater field of view and magnification – up to 12 x zoom. The enhancements to this new product also include a major redesign of the software giving users the following features: - Self-calibrating zoom lens with Field of View error correction

- Improved auto-focus can now find and measure from a distance in one move

- Image stitching – allows a large XY area to be scanned and displayed as a single image

- Live overlays, dimensions and features on the camera (stitched) image, extremely useful for driving the machine to features and showing where the features appear in relation to the rest of the unmeasured the part

- One grab measurement of all features in the Field of View

- One click measurement tool

- All features in area tool

- Make curve scan tool from DXF – no more lost edges on badly prepared or dirty parts

- Optional CAD comparison with touch probe programming from 3D model

CNC 3D Vision System also Includes:- Teach and Repeat programming

- Programmable segmented LED lighting

- High resolution 0.5µm scales for increased accuracy

- CAD import / export

- Scanning & best fitting

- Fully dimensioned part view

- SPC included

- One click output to Excel™

- Autofocus

- 165mm Z axis measuring range on adjustable dovetail slide

- 250mm x 120mm and 300mm x 300mm XY stages available

- Renishaw touch probe (option)

Brochure Make An Enquiry The Venture Plus includes all of the standard Venture features with a greater measuring range. See also Axiom too

Large Measurement Volume

The Venture Plus is available in three models:

VP-6460 with 640mm x 600mm x 250mm measuring range

VP-6490 with 640mm x 900mm x 250mm measuring range

VP-100150 with 1000mm x 1500mm x 400mm measuring range

The bridge type construction is all aluminium resulting in low inertia and low thermal mass. Air bearings are used on all axes and a granite Y beam is used for increased accuracy. This ensures that the machine will expand and contract uniformly with temperature changes ensuring minimal distortion and subsequent errors. Ambient temperature can be compensated for within the Fusion software making Venture Plus ideal for use on the shop floor.

Complete with standard zoom optics and lighting, Venture Plus offers the same level of camera based functionality as every other Venture. Make An Enquiry Features - Teach and repeat programming

- Programmable segmented LED lighting

- High resolution 0.5µm scales for increased accuracy

- CAD import / export

- Scanning & best fitting

- Fully dimensioned part view

- SPC included

- One click output to Excel™

- Autofocus

- Renishaw TP20 touch probe joint

Venture Plus additional features include: - Rigid, low mass bridge construction

- Integral zoom optics

- Patented light table technology

- 250mm Z axis measuring range

- 640mm x 640mm and 640mm x 940mm bridge formats available

- New 1000mm x 1500mm x 400mm model now available

- Optional automatic temperature compensation

- Optional multi function joystick with colour touch screen display

Options include: Multi-function joystick with colour touch screen: - High quality 3 axis hall effect joystick

- Speedwheel for feedrate control

- High resolution colour touch screen

- Easy to use graphic interface

- Hardwired emergency stop button

- Built in speaker for audio feedback

- Left and right handed operation

- CAT5 cable easily extendable

- Remote operation of Windows PC

- Software extendable user interface

VP-6460 640mm x 600mm x 250mm VP-6490 640mm x 900mm x 250mm VP-100105 1000mm x 1500mm x 400mm

MarShaft SCOPE 250 PlusSimple, fast accurate measurement of shafts and cylindrical parts.The MarShaft Scope 250 allows rapid, precision measurement of round and rotationally symmetrical parts. CNC, Turned, Milled and Ground shafts can all be rapidly measured, overcoming traditional difficulties in measuring round parts. Part recognition when a part is loaded further simplifes operator use.

The MarShaft SCOPE 250 plus is a modern, high performance, small capacity, competitively priced shaft measuring machine. Simple, fast, accurate video measuring system for measuring shaft, diameters, lengths, radii, chamfer, grooves, tapers and much more, It enables fast, precise and fully automatic measurement of rotationally symmetrical workpieces in production, cutting time invested in the measuring process and reducing waste. It has a high precision roundness measuring axis (C) and a vertical measuring axis (Z) with a measuring range of 250mm. The jewel in the crown is the state-of-the-art, high resolution CMOS matrix camera (providing the live image) with an image field of 40 x 24mm. The extremely high image acquisition rate of over 120 images per second keeps measuring times to a minimum. Zoom functions allow the smallest details to be measured, which are difficult, and in some cases even impossible, to test with conventional measuring methods. Measuring range 40 mm Dia x 250 mm length. Other machines in the range are available for larger sizes.

Shaft features that can be measured with the MarShaft 250 plus include:

Length, Diameter, Form and position tolernaces, Offsets, Recess width, Bevel width, Intersection points, Radii, Position of Radii, Taper lengths, Hole contours, Angles, Pitches, Widths accross flats, Outer threads etc.

The flexible MarShaft SCOPE 250 plus shaft measuring machine offers fast, precise, fully automatic measurement of rotational symmetrical work-pieces in production.

The MarShaft Scope 350 / 750 / 1000 plus optical shaft measuring systems

Universal, fully automatic optical shaft measurement for testing rotationally symmetrical workpieces. Can be used for both optical and tactile measurements in combination, directly in harsh manufacturing environments.Ideal for a range of engineeering applications, particularly those in the automotive and aerospace industries. Typically turned parts, drive shafts, camshafts. Make Enquiry

VIDEO

Why choose MarShaft SCOPE 350 / 750 / 1000 - Complete measurement of:

- camshafts

- turned parts

- transmission shafts

- drive shafts

- turbocharger shafts

- hydraulic parts

- valves (diesel engine)

- and much more

Product Highlights- Fully automatic optical and tactile shaft measurement

- Highly accurate roundness (C), vertical (Z) and horizontal (X) axes

- Can perform tactile and optical measuring tasks in combination

- Zoom functions allow the smallest details to be measured

- MarShaft EasyShaft software for flexibility and user-friendly operation

Key Numbers- Measuring range length (Z) 350 / 750 / 1000 mm

- Measuring range diameter (X) 80 or 120mm

- Length/diameter resolution 0.01 to 0.0001mm

- Angle resolution 0.01' to 0.0001'

- Length error limit (Z) (um) (2+L/125) L in mm (at 20'C +- 1'C on reference standard)

- Diameter error limit (X) (um) (1.0+L/125) L in mm (at 20'C +- 1'C on reference standard)

???????

The MarShaft Scope 600 / 850 plus 3D optical and tactile shaft measurement

Delivers accurate and repeatable measuring results for almost all rotationally symmetrical workpieces. The combination of optical and tactile sensors, enables 3D functionality and a complete workpiece inspection in one system.Ideal for a range of engineeering applications, particularly those in the automotive and aerospace industries. Typically camshafts, gear shafts, eccentric shafts and shafts with keyways or blind boreholes. Make Enquiry

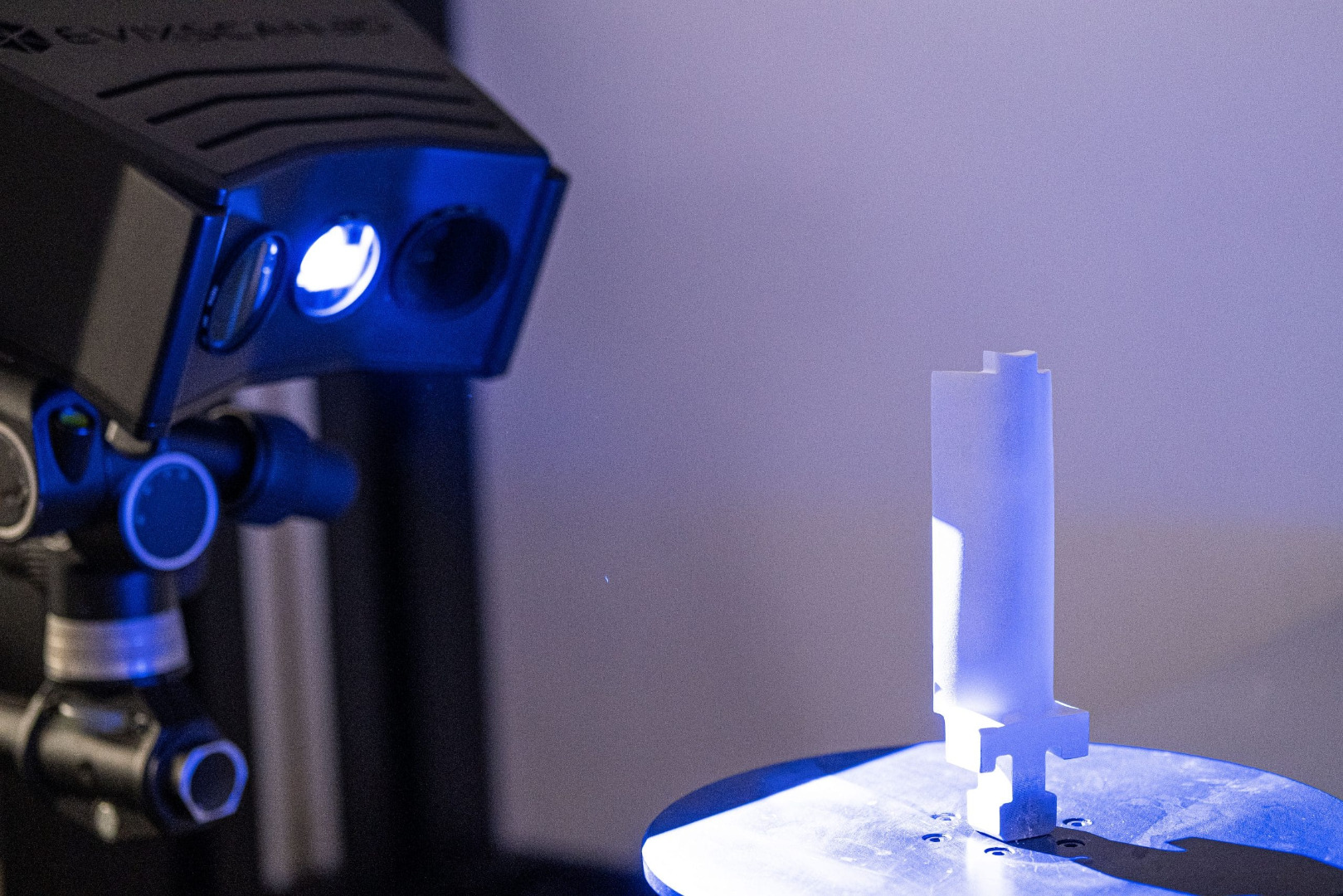

VIDEO Why choose MarShaft 600 / 850 plus 3DProduct HighlightsKey Numbers eviXscan 3D FinePrecisionensures high precision 3D scanning The FinePrecision 3D scanner is perfect as a measuring tool for precision mechanics, especially in areas such as: production of turbine blades, microcircuits, small injection parts, as well as precise numerically processed parts. FinePrecision is also used in scanning implants, in prosthetics, as well as in the watchmaking and jewellery industry. The precision of the scanner also allows it to be used to optimize the 3D printing process. The eviXscan 3D FinePrecision scanner is a device based on the latest generation of high-speed cameras with CMOS sensors and a LED blue light source - the combination of both technologies allows for very accurate reproduction of the scanned surface (accuracy up to 6 µm, resolution 28 µm), even with dark-surface objects.

Make Enquiry Precision 3D scanning in the smallest detailFinePrecision is an optical measuring device that can be used to collect more than 1200 points per square millimeter of scanned area. A single scan gives the possibility to acquire data in the volume of 120 x 60 x 45 mm (larger systems are available, please enquire). Thanks to the blue structured light scanning technology the noise on the scans due to ambient light can be significantly minimized. The combination of a new generation of high-speed cameras with the fast frame collection triggered by the projection system allows you to reduce the scanning time below 1 second.

Control the quality of turbines, blisks, blings or blades with the included airfoil analysis tools. Control X automates the measurement of: - airfoil profiles

- leading and trailing edge position and thickness

- Camber lines

- chord angles and lengths

- 2D twist analysis

Technical specifications: | |

|---|

| Light source type Blue LED | | | Cameras number and resolution 2 x 8.9 Mpix | | | Scanning time 1 second | | | Measuring range 120 x 60 x 32 mm (Larger systems available please enquire) | | | Point density 1 233 pt/mm2 | | | Scanning accuracy up to 0.006 mm | | | Computer connection USB 3.0 | | | Export formats stl, ply, obj, asc, bin | | Software requirements Windows 10 (64-bit),

32 GB RAM, CPU i7,

SSD NVMe 480 GB disk | | | Software eviXscan 3D Suite | |

|